5 Essential Tips for Deciphering Hazard Labels and MSDS

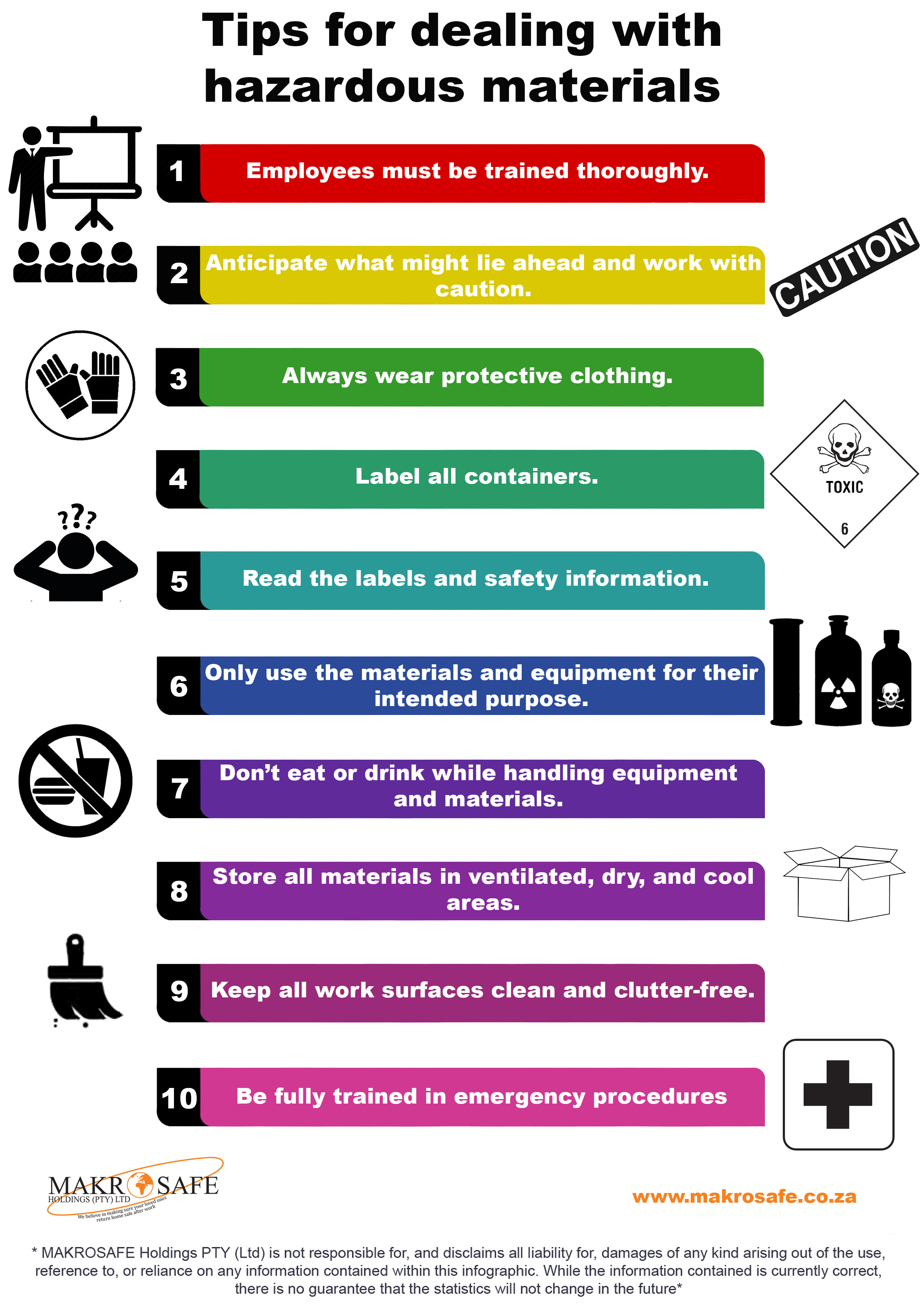

Understanding Hazard Labels and Material Safety Data Sheets (MSDS) is crucial for anyone working with hazardous materials, chemicals, or substances. This blog post will provide you with essential tips to navigate through the complex information these tools present, ensuring your safety and compliance with safety regulations. Let's delve into how you can better understand and utilize these critical resources.

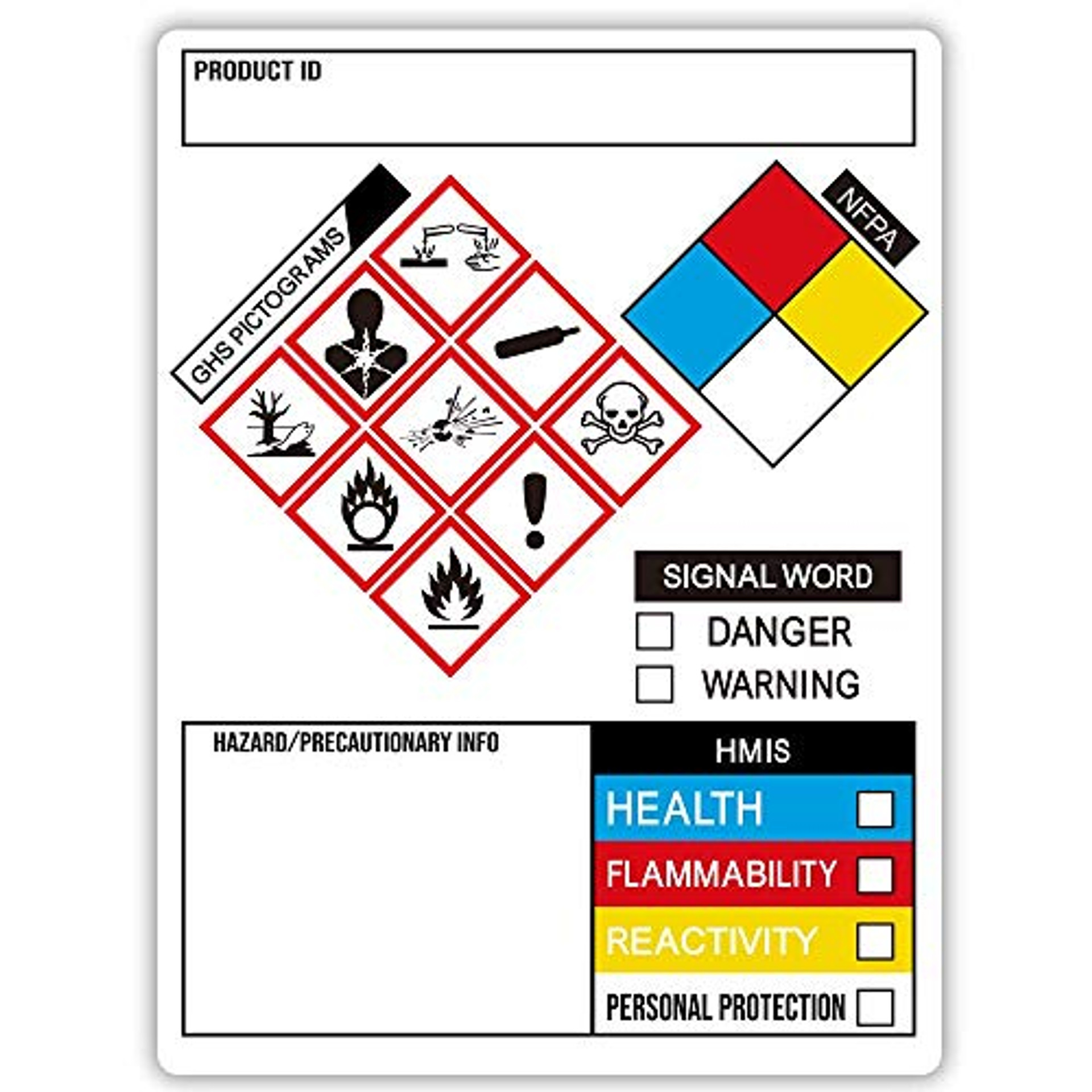

1. Recognize the Symbols and Colors

Before you even pick up a chemical container or access an MSDS, familiarize yourself with the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals. Here’s what you need to know:

- Pictograms: Hazard labels feature nine pictograms, each representing different hazard categories, like health hazards, flammability, or corrosiveness. These symbols are universally understood.

- Color-Coded Labels: GHS uses specific colors to indicate hazard levels:

- Red: Fire hazards

- Blue: Health hazards

- Yellow: Reactivity hazards

- White: Special notices, like a material’s reactivity with water

2. Understand the MSDS Structure

Material Safety Data Sheets are not uniform in format, but there are common sections:

| Section | Information Provided |

|---|---|

| 1. Product and Company Identification | Name, manufacturer details, emergency contact |

| 2. Hazard Identification | Physical and health hazards, precautions for users |

| 3. Composition/Information on Ingredients | Chemical names, trade names, and concentration limits |

| 4. First-Aid Measures | Immediate treatment for exposure |

| … | … |

Each section provides critical information for different scenarios, from emergency response to storage and disposal guidelines.

3. Pay Attention to Specific Hazard Statements and Precautionary Statements

After identifying the symbols, you’ll encounter:

- Hazard Statements: Phrases indicating the nature of the hazards associated with the product.

- Precautionary Statements: Instructions on how to safely use the product or what to do in case of exposure. These statements are critical for preventing accidents.

⚠️ Note: Always read the precautionary statements carefully, especially if you are unsure about handling procedures.

4. Keep Updated with MSDS

Chemical data can change, and so can the MSDS:

- Regularly check for updates or new versions of MSDS for the chemicals you use.

- Employers are required to keep MSDS up-to-date and accessible.

5. Proper Storage and Disposal

The MSDS includes:

- Storage: How to safely store chemicals, considering their compatibility with other materials.

- Disposal: Proper disposal methods, often critical to environmental protection and regulatory compliance.

Ensuring that you follow these guidelines not only promotes safety but also helps in avoiding legal penalties related to improper handling of hazardous materials.

In summary, understanding and correctly interpreting Hazard Labels and MSDS can significantly reduce the risk of accidents and health hazards in any workplace dealing with chemicals. By recognizing symbols, understanding the structure of MSDS, paying attention to precautionary statements, keeping up-to-date, and adhering to proper storage and disposal guidelines, you can maintain a safe environment. This knowledge is not just about compliance; it's about ensuring your wellbeing and those around you.

What do the different colors on hazard labels signify?

+

The GHS color codes indicate hazard types: red for fire hazards, blue for health hazards, yellow for reactivity hazards, and white for special notices.

How often should I check for MSDS updates?

+

It is recommended to check for updates annually or whenever there’s a significant change in the product or its use.

What should I do if I don’t understand a hazard label or MSDS information?

+

If you’re unsure about any part of the MSDS or hazard label, contact your safety officer or the manufacturer for clarification immediately.