5 Ways to Master Segment Measurement Practice 1

Understanding the Basics of Segment Measurement

Segment measurement is fundamental in both basic and advanced mathematics, impacting fields ranging from geometry to computer graphics. To master the art of segment measurement, one must first grasp the core concepts:

- Definition of a Segment: A segment is the part of a line between two designated endpoints.

- Units of Measurement: Common units include meters, centimeters, inches, and feet.

- Tools: Rulers, calipers, and digital tools like CAD software.

Practicing with Precision Tools

To become proficient in segment measurement, one must practice using various tools:

- Rulers and Straightedges: Practice reading different scales on a ruler, understanding the smallest unit for precise measurements.

- Digital Calipers: Learn to use calipers for both internal and external measurements.

- Online Measurement Tools: Familiarize yourself with digital tools like GeoGebra, which can simulate real-world measurement scenarios.

🔍 Note: Always ensure that the tool you are using is accurate and calibrated correctly for the best results.

Developing a Solid Understanding of Error Margins

Measurement is not an exact science; there’s always room for error:

- Understand Precision vs. Accuracy: Precision refers to the consistency of repeated measurements, while accuracy relates to how close a measurement is to the true value.

- Calculate Error Margins: Learn to compute possible errors in your measurements to understand the reliability of your results.

- Tolerance in Engineering: Many industries specify acceptable tolerance levels. Understanding and working within these limits can be crucial.

| Scenario | Expected Precision | Allowable Tolerance |

|---|---|---|

| General Geometry | 0.01 mm | ±0.05 mm |

| Architectural Drawings | 1 mm | ±5 mm |

| Engineering Components | 0.001 mm | ±0.01 mm |

Applying Segment Measurement in Real-World Scenarios

Segment measurement isn’t just an academic exercise; it has practical applications:

- Construction: Measuring for accurate cuts in construction materials.

- Machining: Ensuring parts fit perfectly within tight tolerances.

- Art and Design: Creating precise models or prototypes.

📏 Note: In real-world applications, often measurements need to be translated into different units or systems, requiring a good grasp of unit conversion.

Advanced Techniques in Segment Measurement

Going beyond the basics, here are some advanced techniques to consider:

- Using Trigonometry: Apply trigonometric functions to measure segments indirectly in complex shapes or when direct access is not possible.

- Segment Division: Techniques like trisecting a line with minimal error.

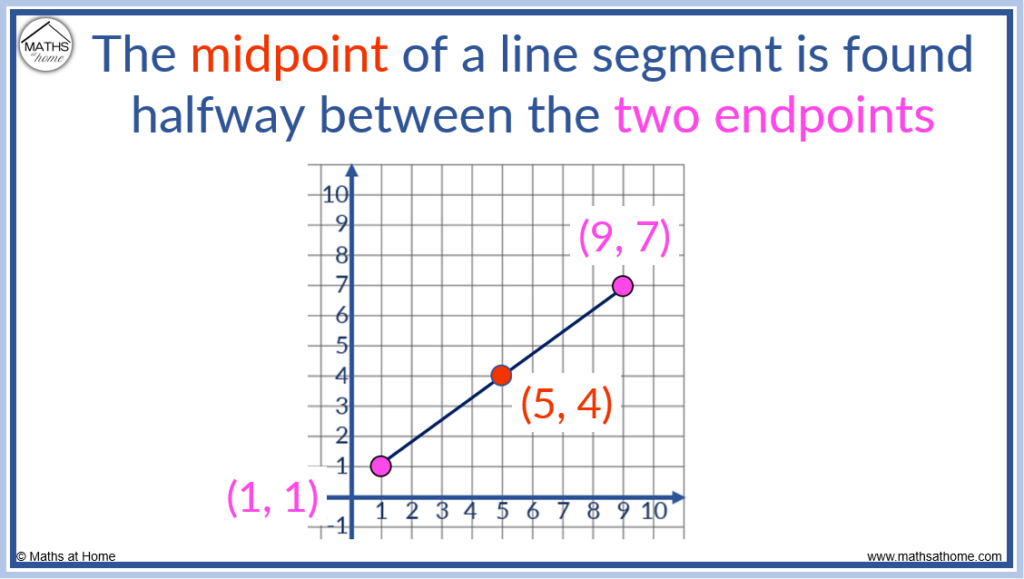

- Coordinate Geometry: Utilize coordinates to calculate distances between points or within shapes.

Mastery of these advanced techniques often requires:

- A strong understanding of mathematics beyond basic geometry.

- Software proficiency for simulations and modeling.

- Ability to adapt measurements in different scenarios.

In sum, mastering segment measurement requires a combination of practical tool use, theoretical knowledge of error margins, and the application of advanced techniques. By developing a solid foundation in these areas, one can achieve precision in their measurements, critical in both professional and educational settings. Whether you're designing a building, manufacturing precision parts, or solving complex geometric problems, accurate segment measurement is key.

What is the difference between precision and accuracy in segment measurement?

+

Precision refers to the consistency or repeatability of a measurement, while accuracy refers to how close a measurement is to the true value. You might take precise measurements that are consistently off by the same amount, thus lacking in accuracy.

How do you handle measurements in different units?

+

Converting between units involves understanding the relationship between those units (e.g., 1 foot = 12 inches). Ensure your tools or calculations account for these relationships, and always check your final result in the desired unit to ensure accuracy.

What are some common tools for segment measurement?

+

Common tools include rulers, tape measures, calipers (digital or vernier), protractors for angles, and software like CAD for precision in design work. Each tool has its application based on the required accuracy and the nature of the task.