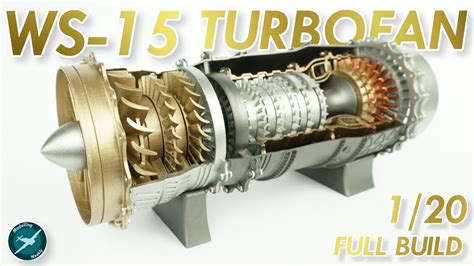

5 WS 15 Turbofan Tips

Introduction to Turbofan Engines

Turbofan engines are a type of jet engine that is widely used in modern aircraft. They are known for their high efficiency and reliability, making them a popular choice for commercial and military aviation. In this article, we will discuss the basics of turbofan engines and provide tips for maintaining and operating them.

How Turbofan Engines Work

A turbofan engine works by using a turbine to drive a fan at the front of the engine. The fan accelerates a large volume of air rearward, producing a significant portion of the engine’s thrust. The turbine is driven by the hot gases produced by the combustion of fuel in the engine’s combustor. The combination of the fan and turbine makes the turbofan engine more efficient than traditional jet engines.

Benefits of Turbofan Engines

Turbofan engines have several benefits that make them a popular choice for aircraft. Some of the benefits include: * High Efficiency: Turbofan engines are more efficient than traditional jet engines, which means they use less fuel to produce the same amount of thrust. * Reliability: Turbofan engines are designed to be reliable and require less maintenance than traditional jet engines. * Low Emissions: Turbofan engines produce fewer emissions than traditional jet engines, making them a more environmentally friendly option.

Turbofan Engine Components

A turbofan engine consists of several components, including: * Fan: The fan is located at the front of the engine and is responsible for accelerating a large volume of air rearward. * Low-Pressure Compressor: The low-pressure compressor is responsible for compressing the air that is drawn into the engine. * High-Pressure Compressor: The high-pressure compressor is responsible for further compressing the air that is drawn into the engine. * Combustor: The combustor is where the fuel is burned to produce the hot gases that drive the turbine. * Turbine: The turbine is driven by the hot gases produced by the combustor and is responsible for driving the fan and compressors.

Tips for Maintaining Turbofan Engines

Maintaining a turbofan engine is crucial to ensuring its reliability and efficiency. Here are some tips for maintaining turbofan engines: * Regular Inspection: Regularly inspect the engine for any signs of wear or damage. * Proper Lubrication: Make sure the engine is properly lubricated to prevent wear and tear on the moving parts. * Filter Maintenance: Regularly clean or replace the engine’s filters to ensure proper airflow and prevent damage to the engine. * Proper Storage: Store the engine in a dry, cool place to prevent corrosion and damage.

📝 Note: Proper maintenance is crucial to extending the life of a turbofan engine.

Tips for Operating Turbofan Engines

Operating a turbofan engine requires careful attention to ensure safe and efficient operation. Here are some tips for operating turbofan engines: * Follow Procedures: Follow established procedures for starting and operating the engine. * Monitor Performance: Monitor the engine’s performance and adjust as necessary to ensure optimal operation. * Avoid Overloading: Avoid overloading the engine, as this can cause damage and reduce its lifespan. * Use Proper Fuel: Use the proper type and amount of fuel to ensure optimal engine performance.

Common Issues with Turbofan Engines

Like any complex machine, turbofan engines can experience issues that affect their performance and reliability. Some common issues include: * Corrosion: Corrosion can occur when the engine is exposed to moisture and salt. * Wear and Tear: Wear and tear can occur on the moving parts of the engine, reducing its efficiency and reliability. * Clogging: Clogging can occur in the engine’s filters and fuel system, reducing its performance and efficiency.

| Issue | Cause | Solution |

|---|---|---|

| Corrosion | Moisture and salt exposure | Proper storage and maintenance |

| Wear and Tear | Prolonged use and lack of maintenance | Regular inspection and maintenance |

| Clogging | Dirty filters and fuel system | Regular cleaning and replacement of filters |

In summary, turbofan engines are complex machines that require careful maintenance and operation to ensure their reliability and efficiency. By following the tips outlined in this article, operators can help extend the life of their turbofan engines and ensure safe and efficient operation.

What is the main benefit of turbofan engines?

+

The main benefit of turbofan engines is their high efficiency, which makes them more fuel-efficient than traditional jet engines.

How do I maintain my turbofan engine?

+

To maintain your turbofan engine, regularly inspect the engine for signs of wear or damage, properly lubricate the engine, and clean or replace the engine’s filters.

What are some common issues with turbofan engines?

+

Some common issues with turbofan engines include corrosion, wear and tear, and clogging. These issues can be prevented or resolved with proper maintenance and operation.