5 Ways To Plot Control Chart

Introduction to Control Charts

Control charts are a type of statistical process control tool used to monitor and control processes in various industries, including manufacturing, healthcare, and finance. They help to identify trends, patterns, and anomalies in data, allowing for timely interventions to prevent defects or errors. In this article, we will explore 5 ways to plot control charts, highlighting their importance, benefits, and applications.

What is a Control Chart?

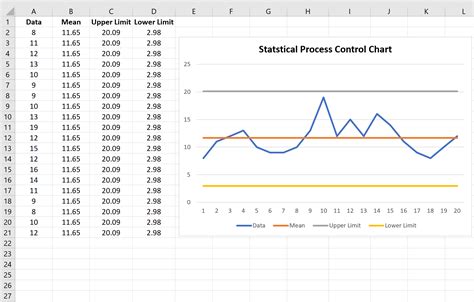

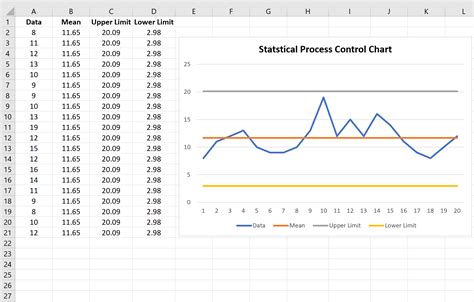

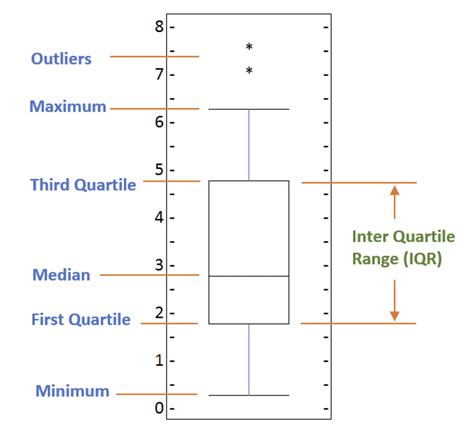

A control chart is a graphical representation of data over time, displaying the performance of a process or system. It consists of a center line, which represents the average or target value, and upper and lower control limits, which indicate the acceptable range of variation. By plotting data on a control chart, you can quickly identify when a process is in control or out of control, allowing for corrective actions to be taken.

5 Ways to Plot Control Charts

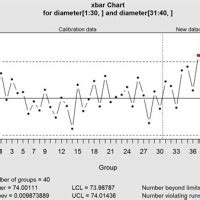

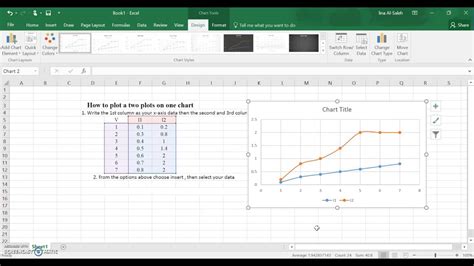

Here are 5 ways to plot control charts, each with its own strengths and weaknesses: * X-Bar Chart: Used to monitor the average value of a process over time. It is commonly used in manufacturing to track the average dimension of a product. * R-Chart: Used to monitor the range of values in a process. It is commonly used in conjunction with the X-Bar chart to monitor the variability of a process. * P-Chart: Used to monitor the proportion of defective items in a process. It is commonly used in quality control to track the percentage of defects. * NP-Chart: Used to monitor the number of defective items in a process. It is commonly used in quality control to track the number of defects. * C-Chart: Used to monitor the count of defects in a process. It is commonly used in quality control to track the number of defects per unit.

Benefits of Control Charts

Control charts offer several benefits, including: * Improved quality: By monitoring processes and identifying anomalies, control charts help to prevent defects and errors. * Increased efficiency: By identifying trends and patterns, control charts help to optimize processes and reduce waste. * Reduced costs: By preventing defects and errors, control charts help to reduce costs associated with rework, scrap, and warranty claims. * Enhanced customer satisfaction: By delivering high-quality products and services, control charts help to enhance customer satisfaction and loyalty.

Applications of Control Charts

Control charts have a wide range of applications, including: * Manufacturing: Control charts are used to monitor production processes, track quality, and prevent defects. * Healthcare: Control charts are used to monitor patient outcomes, track quality, and prevent medical errors. * Finance: Control charts are used to monitor financial processes, track quality, and prevent errors. * Service industries: Control charts are used to monitor service processes, track quality, and prevent errors.

📝 Note: Control charts are a powerful tool for monitoring and controlling processes, but they require careful planning, implementation, and maintenance to ensure their effectiveness.

How to Create a Control Chart

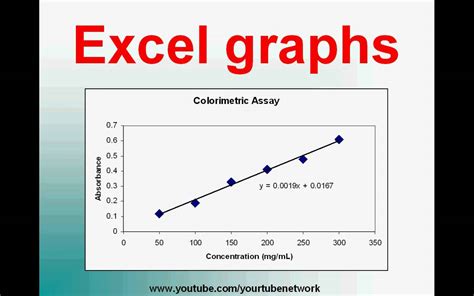

Creating a control chart involves several steps, including: * Define the process: Identify the process to be monitored and controlled. * Collect data: Collect data on the process, including measurements, counts, or proportions. * Calculate control limits: Calculate the center line, upper control limit, and lower control limit. * Plot data: Plot the data on the control chart, using a time series plot or a scatter plot. * Interpret results: Interpret the results, identifying trends, patterns, and anomalies.

| Control Chart Type | Center Line | Upper Control Limit | Lower Control Limit |

|---|---|---|---|

| X-Bar Chart | Mean | Mean + 3σ | Mean - 3σ |

| R-Chart | Mean range | Mean range + 3σ | Mean range - 3σ |

| P-Chart | Proportion | Proportion + 3σ | Proportion - 3σ |

| NP-Chart | Number of defects | Number of defects + 3σ | Number of defects - 3σ |

| C-Chart | Count of defects | Count of defects + 3σ | Count of defects - 3σ |

In summary, control charts are a powerful tool for monitoring and controlling processes, offering several benefits, including improved quality, increased efficiency, reduced costs, and enhanced customer satisfaction. By understanding the different types of control charts and how to create them, you can apply these tools to various industries and applications, driving continuous improvement and excellence.

What is the purpose of a control chart?

+

The purpose of a control chart is to monitor and control processes, identifying trends, patterns, and anomalies in data.

What are the benefits of using control charts?

+

The benefits of using control charts include improved quality, increased efficiency, reduced costs, and enhanced customer satisfaction.

How do I create a control chart?

+

To create a control chart, define the process, collect data, calculate control limits, plot data, and interpret results.