5 Ways Gasket Few Pounds

Introduction to Gasket Materials

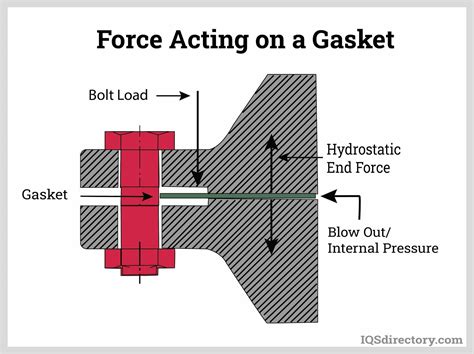

Gaskets are mechanical seals used to fill the space between two mating surfaces, preventing leaks and maintaining the pressure or vacuum within a system. They are commonly used in pipes, engines, and other machinery. The choice of gasket material is crucial, as it determines the gasket’s performance and longevity. Various materials are used to manufacture gaskets, including rubber, silicone, cork, paper, and metal. Each material has its unique properties, advantages, and applications.

Types of Gasket Materials

There are several types of gasket materials, each with its own characteristics and uses. Some of the most common types include: * Rubber Gaskets: Made from natural or synthetic rubber, these gaskets are flexible and resistant to compression. They are suitable for low-pressure applications and are often used in pipes and fittings. * Cork Gaskets: Made from cork, these gaskets are highly compressible and have excellent sealing properties. They are often used in low-pressure applications where a high level of sealing is required. * Paper Gaskets: Made from paper or paper-like materials, these gaskets are inexpensive and easy to manufacture. They are often used in low-pressure applications where a high level of sealing is not required. * Metal Gaskets: Made from metal, these gaskets are highly durable and resistant to high pressures and temperatures. They are often used in high-pressure applications where a high level of sealing is required. * Silicone Gaskets: Made from silicone, these gaskets are highly flexible and resistant to extreme temperatures. They are often used in high-temperature applications where a high level of sealing is required.

Applications of Gaskets

Gaskets have a wide range of applications in various industries, including: * Automotive Industry: Gaskets are used in engines, transmissions, and other components to prevent leaks and maintain pressure. * Aerospace Industry: Gaskets are used in aircraft and spacecraft to prevent leaks and maintain pressure in critical systems. * Industrial Equipment: Gaskets are used in pumps, valves, and other equipment to prevent leaks and maintain pressure. * Plumbing: Gaskets are used in pipes and fittings to prevent leaks and maintain pressure.

Benefits of Using Gaskets

Using gaskets provides several benefits, including: * Leak Prevention: Gaskets prevent leaks and maintain pressure in systems, reducing the risk of accidents and injuries. * Increased Efficiency: Gaskets help to maintain pressure and prevent leaks, increasing the efficiency of systems and reducing energy consumption. * Reduced Maintenance: Gaskets reduce the need for maintenance and repairs, as they prevent leaks and maintain pressure in systems. * Improved Safety: Gaskets improve safety by preventing leaks and maintaining pressure in critical systems.

Common Issues with Gaskets

Despite their importance, gaskets can experience common issues, including: * Leakage: Gaskets can leak due to improper installation, damage, or wear and tear. * Compression Set: Gaskets can experience compression set, which reduces their sealing properties over time. * Corrosion: Gaskets can corrode due to exposure to chemicals or extreme temperatures. * Damage: Gaskets can be damaged due to over-tightening, over-compression, or physical stress.

🔧 Note: Regular inspection and maintenance of gaskets can help to prevent common issues and ensure optimal performance.

In the world of gaskets, a few pounds can make a significant difference. The weight and density of a gasket can affect its performance, longevity, and overall effectiveness. A gasket that is too light or too heavy can compromise the sealing properties of the system, leading to leaks, inefficiencies, and potential accidents. Therefore, it is essential to choose the right gasket material and design for the specific application, taking into account factors such as pressure, temperature, and corrosion resistance.

To summarize, gaskets play a crucial role in maintaining the integrity of systems and preventing leaks. By understanding the different types of gasket materials, their applications, and common issues, we can ensure optimal performance, efficiency, and safety. Whether it’s a few pounds or a few kilograms, the weight and density of a gasket can have a significant impact on its effectiveness. By choosing the right gasket for the job, we can prevent common issues, reduce maintenance, and improve overall safety.

What are the most common types of gasket materials?

+

The most common types of gasket materials include rubber, silicone, cork, paper, and metal. Each material has its unique properties and applications.

What are the benefits of using gaskets?

+

Using gaskets provides several benefits, including leak prevention, increased efficiency, reduced maintenance, and improved safety.

How can I prevent common issues with gaskets?

+

Regular inspection and maintenance of gaskets can help to prevent common issues such as leakage, compression set, corrosion, and damage.