5 Ways Calculate Aircraft Hours

Introduction to Calculating Aircraft Hours

Calculating aircraft hours is a crucial aspect of aviation, as it directly affects the maintenance, operational costs, and overall efficiency of an aircraft. The accuracy of these calculations can impact the safety and reliability of flights, making it essential for aircraft owners, operators, and maintenance personnel to understand the different methods used. In this article, we will delve into five ways to calculate aircraft hours, exploring the significance of each method and how they contribute to the broader scope of aircraft management.

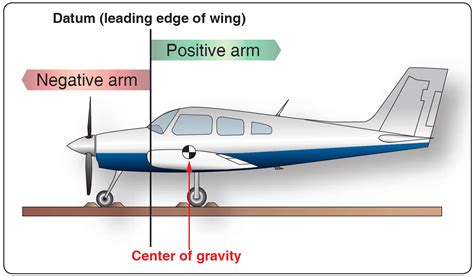

Understanding Aircraft Hours

Before diving into the calculation methods, it’s essential to understand what aircraft hours represent. Aircraft hours, also known as flight hours or airframe hours, refer to the total time an aircraft has been in operation. This includes the time spent flying, taxiing, and performing other ground operations. Accurate tracking of aircraft hours is vital for scheduling maintenance, assessing wear and tear, and planning for future operations.

Method 1: Hobbs Meter Reading

The most common method of calculating aircraft hours is by using a Hobbs meter. A Hobbs meter is an instrument installed in the aircraft’s cockpit that records the total time the engine is running. This method provides a direct and accurate measurement of the aircraft’s operational time. The Hobbs meter starts when the engine is turned on and stops when it is turned off, giving a precise reading of the time elapsed.

Method 2: Tachometer Reading

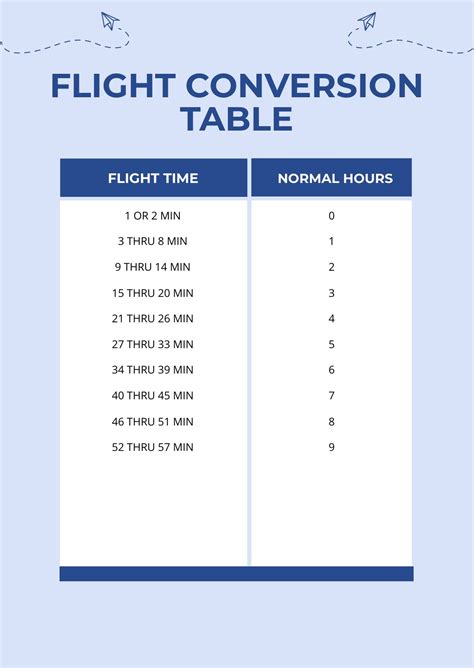

Another method involves using the tachometer reading. The tachometer measures the engine’s RPM (revolutions per minute), which can be used to estimate the aircraft’s operational time. By comparing the tachometer reading at the start and end of a flight, operators can calculate the total time the engine was running. However, this method may not be as accurate as the Hobbs meter, as it does not account for variations in engine speed during different phases of flight.

Method 3: Flight Log Entries

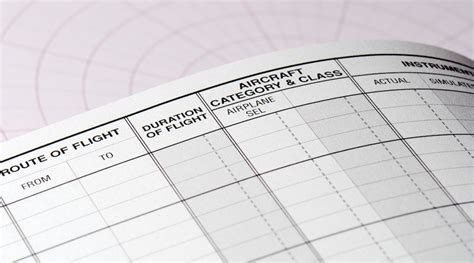

Pilots and aircraft operators also use flight log entries to track aircraft hours. After each flight, the pilot records the flight time, including the time spent taxiing, taking off, cruising, and landing. These entries are then used to calculate the total aircraft hours. This method relies on the accuracy of the pilot’s log entries and may be subject to human error. Nevertheless, it provides a comprehensive record of the aircraft’s operational history.

Method 4: Automated Flight Tracking Systems

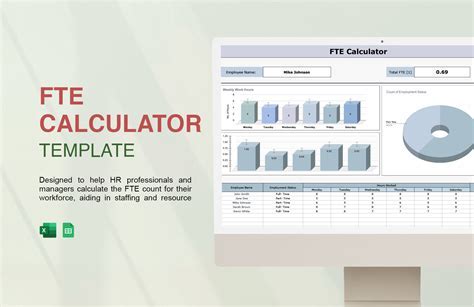

With the advent of technology, automated flight tracking systems have become increasingly popular. These systems use GPS and other sensors to track the aircraft’s location, altitude, and speed, providing real-time data on the aircraft’s operational status. This method offers high accuracy and can be integrated with other aircraft management systems to streamline operations.

Method 5: Maintenance Records

Finally, maintenance records can also be used to calculate aircraft hours. By analyzing the maintenance history of the aircraft, including the dates and times of routine inspections, repairs, and replacements, operators can estimate the total time the aircraft has been in operation. This method is particularly useful for identifying trends and patterns in the aircraft’s maintenance needs, allowing for more effective planning and resource allocation.

📝 Note: It is essential to ensure that all methods of calculating aircraft hours are regularly calibrated and verified to maintain accuracy and reliability.

Comparison of Calculation Methods

Each of the five methods has its advantages and disadvantages. The Hobbs meter reading is widely considered the most accurate method, while the tachometer reading and flight log entries may be subject to some degree of error. Automated flight tracking systems offer real-time data and high accuracy, but may require significant investment in technology and infrastructure. Maintenance records provide valuable insights into the aircraft’s maintenance history, but may not always reflect the actual operational time.

| Method | Accuracy | Advantages | Disadvantages |

|---|---|---|---|

| Hobbs Meter Reading | High | Direct measurement, easy to use | May not account for variations in engine speed |

| Tachometer Reading | Medium | Provides estimate of operational time | May be subject to human error, less accurate than Hobbs meter |

| Flight Log Entries | Medium | Comprehensive record of operational history | May be subject to human error, relies on pilot's log entries |

| Automated Flight Tracking Systems | High | Real-time data, high accuracy, integrated with other systems | Requires significant investment in technology and infrastructure |

| Maintenance Records | Medium | Provides insights into maintenance history, helps with planning | May not always reflect actual operational time, subject to human error |

In summary, calculating aircraft hours is a critical aspect of aviation that requires accuracy and reliability. The five methods discussed in this article offer different approaches to tracking aircraft hours, each with its strengths and weaknesses. By understanding the advantages and disadvantages of each method, aircraft owners, operators, and maintenance personnel can make informed decisions about which method to use and how to ensure the accuracy and reliability of their calculations.

As we reflect on the importance of calculating aircraft hours, it becomes clear that this process is not just a matter of record-keeping, but a vital component of ensuring the safety, efficiency, and reliability of aircraft operations. By adopting a comprehensive approach to tracking aircraft hours, the aviation industry can continue to evolve and improve, providing better services to passengers and cargo alike.

What is the most accurate method of calculating aircraft hours?

+

The most accurate method of calculating aircraft hours is by using a Hobbs meter, which provides a direct measurement of the time the engine is running.

Can flight log entries be used to calculate aircraft hours?

+

Yes, flight log entries can be used to calculate aircraft hours, but this method relies on the accuracy of the pilot’s log entries and may be subject to human error.

What are the advantages of using automated flight tracking systems to calculate aircraft hours?

+

Automated flight tracking systems offer real-time data, high accuracy, and can be integrated with other aircraft management systems to streamline operations.

Related Terms:

- Aircraft hours calculator free

- Aircraft hours calculator app

- Aircraft hours calculator international

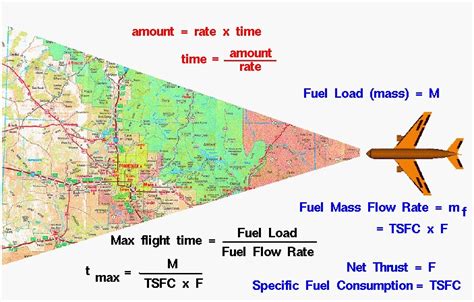

- Flight time distance calculator

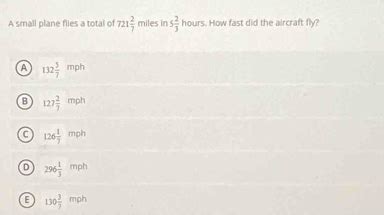

- Flight time calculator with speed

- Pilot logbook calculator