Materials That Can Effectively Cut or Pierce Through Steel

Steel is a tough and versatile metal alloy known for its strength and durability. However, when it comes to cutting or piercing through steel, there are several materials that can get the job done effectively.

Cutting Through Steel

Cutting through steel requires materials with exceptional hardness and toughness. Here are some of the most effective materials for cutting through steel:

- Tungsten Carbide: Known for its exceptional hardness, tungsten carbide is a popular choice for cutting tools, such as saw blades and drill bits. Its high density and hardness enable it to withstand the rigors of cutting through steel.

- Diamond: Diamond is one of the hardest substances known, making it an ideal material for cutting through steel. Diamond-coated saw blades and drill bits are commonly used in industrial applications where high precision and accuracy are required.

- Cobalt-Chromium Alloys: Cobalt-chromium alloys, such as Stellite, are known for their exceptional hardness and wear resistance. These alloys are often used in cutting tools, such as drill bits and saw blades, where high toughness and resistance to wear are required.

Piercing Through Steel

Piercing through steel requires materials with high hardness and toughness, as well as the ability to withstand high temperatures. Here are some of the most effective materials for piercing through steel:

- Tungsten: Tungsten is a hard, dense metal with a high melting point, making it an ideal material for piercing through steel. Tungsten-tipped drill bits and punches are commonly used in industrial applications where high precision and accuracy are required.

- Molybdenum: Molybdenum is a hard, silver-white metal with a high melting point, making it an ideal material for piercing through steel. Molybdenum-tipped drill bits and punches are commonly used in industrial applications where high precision and accuracy are required.

- Chromium-Molybdenum Steel: Chromium-molybdenum steel, also known as chrome-moly steel, is a high-strength, low-alloy steel with a high melting point. This steel alloy is often used in applications where high strength, toughness, and resistance to wear are required, such as in drilling and punching operations.

Other Materials

In addition to the materials mentioned above, there are several other materials that can effectively cut or pierce through steel, including:

- High-Speed Steel: High-speed steel, also known as HSS, is a high-strength, high-toughness steel alloy with a high melting point. This steel alloy is often used in cutting tools, such as drill bits and saw blades, where high precision and accuracy are required.

- Ceramic-Coated Tools: Ceramic-coated tools, such as saw blades and drill bits, are designed to provide exceptional wear resistance and high precision cutting capabilities.

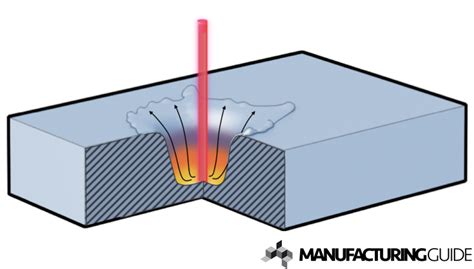

- Laser Cutting: Laser cutting is a non-contact cutting method that uses a high-powered laser beam to cut through steel. This method is commonly used in industrial applications where high precision and accuracy are required.

🔩 Note: The effectiveness of these materials can vary depending on the specific application and the type of steel being cut or pierced.

| Material | Hardness (Mohs) | Density (g/cm³) | Melting Point (°C) |

|---|---|---|---|

| Tungsten Carbide | 8.5-9 | 14.5-15.5 | 2800-3000 |

| Diamond | 10 | 3.5-4.0 | 3800-4000 |

| Cobalt-Chromium Alloys | 8-9 | 8-9 | 1300-1400 |

| Tungsten | 8.5-9 | 19.3-19.5 | 3422-3427 |

| Molybdenum | 5.5-6 | 10.2-10.4 | 2623-2627 |

| Chromium-Molybdenum Steel | 6-7 | 7.9-8.1 | 1450-1550 |

In conclusion, when it comes to cutting or piercing through steel, there are several materials that can get the job done effectively. The choice of material depends on the specific application, the type of steel being cut or pierced, and the desired level of precision and accuracy.

What is the hardest material that can cut through steel?

+

Diamond is the hardest material that can cut through steel, with a Mohs hardness of 10.

What is the most common material used for piercing through steel?

+

Tungsten is a popular material used for piercing through steel due to its high hardness and melting point.

Can ceramic-coated tools cut through steel?

+

Yes, ceramic-coated tools can cut through steel, but they are not as effective as other materials like tungsten carbide or diamond.