5 Ways Industrial Engineers Boost Business Efficiency

Unlocking the Power of Industrial Engineers: Boosting Business Efficiency

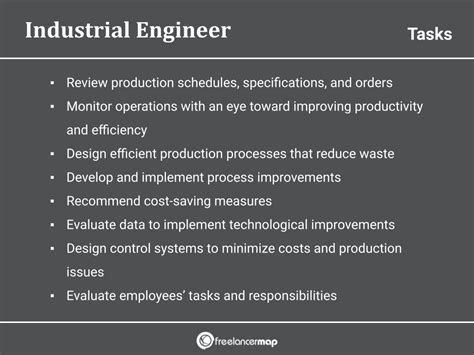

In today’s fast-paced and competitive business landscape, companies are constantly seeking innovative ways to optimize their operations and gain a competitive edge. One key to achieving this is by leveraging the expertise of industrial engineers. These professionals specialize in designing, implementing, and optimizing processes, systems, and facilities to improve efficiency, productivity, and overall business performance. In this article, we will explore five ways industrial engineers can boost business efficiency.

1. Streamlining Processes and Operations

Industrial engineers use various techniques, such as lean manufacturing and Six Sigma, to identify and eliminate inefficiencies in business processes. By analyzing and mapping workflows, they can pinpoint bottlenecks, reduce waste, and implement improvements that increase productivity and reduce costs. For example, an industrial engineer might:

- Analyze production workflows to identify opportunities for automation or process simplification

- Implement just-in-time (JIT) inventory systems to reduce inventory costs and improve supply chain efficiency

- Develop and implement standardized work procedures to improve consistency and reduce errors

📝 Note: By streamlining processes, businesses can reduce waste, improve quality, and increase productivity, leading to cost savings and improved competitiveness.

2. Optimizing Supply Chain and Logistics

Industrial engineers can help businesses optimize their supply chain and logistics operations by:

- Analyzing transportation networks and routes to reduce costs and improve delivery times

- Implementing inventory management systems to optimize inventory levels and reduce stockouts

- Developing and implementing warehouse layout and design improvements to increase storage capacity and reduce material handling costs

| Benefits of Supply Chain Optimization | Description |

|---|---|

| Reduced Costs | Lower transportation, inventory, and warehousing costs |

| Improved Delivery Times | Faster and more reliable delivery of products to customers |

| Increased Efficiency | Improved supply chain visibility and reduced manual errors |

3. Improving Product Design and Development

Industrial engineers can help businesses improve their product design and development processes by:

- Applying design for manufacturability (DFM) principles to reduce production costs and improve product quality

- Using computer-aided design (CAD) and computer-aided engineering (CAE) tools to optimize product design and reduce prototyping costs

- Developing and implementing design for assembly (DFA) guidelines to improve product manufacturability and reduce assembly costs

📈 Note: By improving product design and development, businesses can reduce production costs, improve product quality, and increase customer satisfaction.

4. Enhancing Workplace Safety and Ergonomics

Industrial engineers can help businesses improve workplace safety and ergonomics by:

- Conducting workplace hazard assessments to identify potential safety risks

- Developing and implementing ergonomic guidelines to reduce worker fatigue and improve productivity

- Designing and implementing safety training programs to reduce workplace accidents and injuries

5. Implementing Technology and Automation

Industrial engineers can help businesses implement technology and automation solutions to improve efficiency and productivity. This may include:

- Implementing robotics and automation systems to improve production efficiency and reduce labor costs

- Developing and implementing IoT (Internet of Things) solutions to improve supply chain visibility and reduce inventory costs

- Implementing data analytics and business intelligence tools to improve decision-making and reduce costs

In conclusion, industrial engineers play a critical role in helping businesses optimize their operations and improve efficiency. By streamlining processes, optimizing supply chain and logistics, improving product design and development, enhancing workplace safety and ergonomics, and implementing technology and automation, businesses can gain a competitive edge and achieve long-term success.

What is the role of an industrial engineer in business?

+

Industrial engineers design, implement, and optimize processes, systems, and facilities to improve efficiency, productivity, and overall business performance.

How can industrial engineers improve supply chain efficiency?

+

Industrial engineers can analyze transportation networks and routes, implement inventory management systems, and develop and implement warehouse layout and design improvements to optimize supply chain efficiency.

What are some benefits of implementing technology and automation in business?

+

Implementing technology and automation can improve production efficiency, reduce labor costs, and improve supply chain visibility, among other benefits.