Military

Redesigning Weapon Production Line Costs

Introduction to Redesigning Weapon Production Line Costs

The production of weapons is a complex process that involves various stages, from design and development to manufacturing and testing. The cost of producing weapons can be extremely high, and it is essential to optimize the production line to minimize costs without compromising on quality. In this blog post, we will discuss the importance of redesigning weapon production line costs and provide tips on how to achieve it.

Understanding the Current Production Line

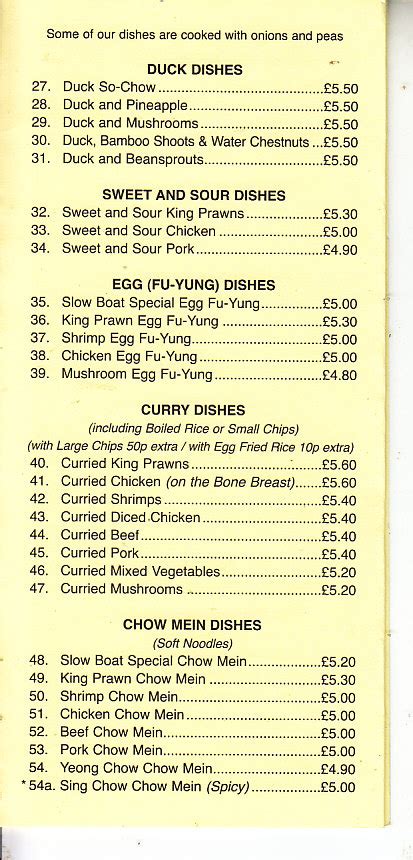

Before redesigning the production line, it is crucial to understand the current process. This involves analyzing the different stages of production, identifying bottlenecks, and determining areas where costs can be reduced. Some of the key factors to consider include: * Material costs: The cost of raw materials, such as metals and electronics, can be a significant portion of the overall production cost. * Labor costs: The cost of hiring and training skilled workers can be high, especially if the production process requires specialized skills. * Equipment costs: The cost of purchasing and maintaining equipment, such as machinery and tools, can also be substantial. * Overhead costs: The cost of maintaining a facility, including utilities and insurance, can add up quickly.

Identifying Areas for Cost Reduction

Once the current production line is understood, the next step is to identify areas where costs can be reduced. Some potential areas for cost reduction include: * Streamlining the production process: Eliminating unnecessary steps or combining tasks can help reduce labor costs and increase efficiency. * Implementing lean manufacturing: Reducing waste and minimizing inventory can help reduce material costs and improve overall efficiency. * Investing in automation: Automating certain tasks can help reduce labor costs and improve accuracy. * Renegotiating contracts with suppliers: Negotiating better prices with suppliers can help reduce material costs.

Implementing Cost-Reduction Strategies

After identifying areas for cost reduction, the next step is to implement strategies to achieve these reductions. Some potential strategies include: * Conducting regular inventory audits: Regularly reviewing inventory levels can help identify areas where waste can be reduced. * Implementing a just-in-time inventory system: Ordering materials just in time can help reduce inventory costs and minimize waste. * Providing training to employees: Providing employees with training on efficient production techniques can help reduce labor costs and improve overall efficiency. * Investing in energy-efficient equipment: Investing in energy-efficient equipment can help reduce overhead costs and minimize the environmental impact of production.

| Cost-Reduction Strategy | Potential Cost Savings |

|---|---|

| Streamlining the production process | 10-20% |

| Implementing lean manufacturing | 15-30% |

| Investing in automation | 20-40% |

| Renegotiating contracts with suppliers | 5-15% |

💡 Note: The potential cost savings listed in the table are approximate and may vary depending on the specific production line and cost-reduction strategies implemented.

Maintaining Quality and Efficiency

While reducing costs is essential, it is also crucial to maintain quality and efficiency in the production line. Some ways to achieve this include: * Implementing quality control checks: Regularly inspecting products for quality can help ensure that they meet the required standards. * Providing ongoing training to employees: Providing employees with ongoing training can help ensure that they have the skills and knowledge needed to maintain quality and efficiency. * Investing in maintenance and repairs: Regularly maintaining and repairing equipment can help prevent downtime and ensure that the production line runs smoothly. * Continuously monitoring and evaluating the production line: Regularly monitoring and evaluating the production line can help identify areas for improvement and ensure that quality and efficiency are maintained.

In the end, redesigning weapon production line costs requires a thorough understanding of the current production line, identifying areas for cost reduction, and implementing strategies to achieve these reductions. By streamlining the production process, implementing lean manufacturing, investing in automation, and renegotiating contracts with suppliers, manufacturers can reduce costs while maintaining quality and efficiency.