7 Types of Heavy Equipment Operators

7 Types of Heavy Equipment Operators

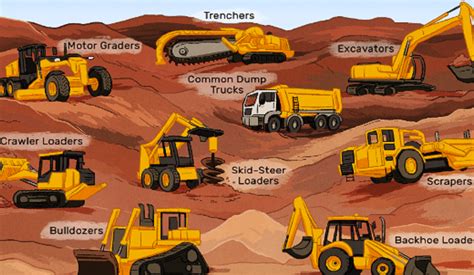

The construction industry relies heavily on skilled heavy equipment operators to ensure projects are completed efficiently and safely. These operators use a variety of machines to move earth, lift materials, and perform other tasks that require precision and expertise. Here are seven types of heavy equipment operators and their responsibilities:

1. Crane Operator

Crane operators are responsible for operating cranes, which are used to lift and move heavy loads on construction sites. They must be skilled in operating different types of cranes, including tower cranes, mobile cranes, and overhead cranes. Crane operators must also be able to read blueprints and follow instructions from site managers to ensure loads are placed correctly.

2. Bulldozer Operator

Bulldozer operators use bulldozers to move earth and other materials on construction sites. They must be skilled in operating the machine’s tracks, blades, and ripper attachments to achieve the desired results. Bulldozer operators work closely with site managers to ensure that the terrain is graded to the correct specifications.

3. Excavator Operator

Excavator operators use excavators, also known as backhoes, to dig trenches, foundations, and other excavations on construction sites. They must be skilled in operating the machine’s boom, stick, and bucket to achieve the desired results. Excavator operators must also be able to read blueprints and follow instructions from site managers to ensure that the excavations are dug to the correct specifications.

4. Dump Truck Operator

Dump truck operators use dump trucks to transport materials, such as soil, gravel, and sand, on construction sites. They must be skilled in operating the truck’s hydraulics and dumping mechanisms to ensure safe and efficient delivery of materials.

5. Grader Operator

Grader operators use graders to grade and level terrain on construction sites. They must be skilled in operating the machine’s blades and hydraulic systems to achieve the desired results. Grader operators work closely with site managers to ensure that the terrain is graded to the correct specifications.

6. Asphalt Paver Operator

Asphalt paver operators use asphalt pavers to lay asphalt on roads, highways, and other surfaces. They must be skilled in operating the machine’s screed and auger systems to achieve the desired results. Asphalt paver operators must also be able to read blueprints and follow instructions from site managers to ensure that the asphalt is laid to the correct specifications.

7. Telehandler Operator

Telehandler operators use telehandlers, also known as boom lifts, to lift and move materials on construction sites. They must be skilled in operating the machine’s boom, forks, and hydraulic systems to achieve the desired results. Telehandler operators must also be able to read blueprints and follow instructions from site managers to ensure that materials are placed correctly.

📝 Note: Heavy equipment operators must undergo extensive training and obtain certifications to operate these machines safely and efficiently.

Each type of heavy equipment operator plays a critical role in the construction process. By understanding the different types of heavy equipment operators and their responsibilities, construction companies can ensure that their projects are completed on time, within budget, and to the required quality standards.

To become a heavy equipment operator, one must obtain the necessary training and certifications. Here are the steps to become a heavy equipment operator:

- Obtain a high school diploma or equivalent

- Complete a training program in heavy equipment operation

- Obtain certifications from organizations such as the National Center for Construction Education and Research (NCCER) or the International Union of Operating Engineers (IUOE)

- Gain experience by working as an apprentice or assistant to an experienced heavy equipment operator

- Continuously update skills and knowledge by attending workshops and seminars

In conclusion, heavy equipment operators play a vital role in the construction industry. By understanding the different types of heavy equipment operators and their responsibilities, construction companies can ensure that their projects are completed safely, efficiently, and to the required quality standards.

What is the average salary of a heavy equipment operator?

+

The average salary of a heavy equipment operator varies depending on the type of machine, location, and experience. However, according to the Bureau of Labor Statistics, the median annual salary for heavy equipment operators was $48,160 in May 2020.

Do heavy equipment operators need to be physically fit?

+

Yes, heavy equipment operators need to be physically fit to operate machines safely and efficiently. They must be able to lift heavy objects, work in extreme weather conditions, and sit for long periods.

Can heavy equipment operators work independently?

+

Yes, heavy equipment operators can work independently, but they often work as part of a team to complete construction projects. They must be able to follow instructions from site managers and communicate with other team members to ensure safe and efficient operation.