5 Ways to Handle Collapsed Areas in PTC MCAD

When working with mechanical design software like PTC Creo Parametric (often known as Pro/ENGINEER), handling collapsed areas or regions is crucial for ensuring the design's integrity and accuracy. Collapsed areas can occur due to various reasons like improper geometry definition, meshing issues, or interference checks. Here, we'll explore five effective ways to manage these areas to enhance your design workflow and maintain model quality:

1. Rebuild and Verify Geometry

One of the primary steps in addressing collapsed areas is to rebuild and verify your geometry:

- Regenerate: Use the ‘Regenerate’ command to update the model. Sometimes, simply regenerating can resolve minor issues.

- Check Geometry: Use tools like ‘Verify Geometry’ or ‘Model Check’ to find anomalies. This tool scans your model for non-manifold geometry, slivers, or improper intersections that could lead to collapsed areas.

⚠️ Note: Regular geometry checks are preventive measures, ensuring your design stays free from unexpected collapse issues.

2. Adjusting Model Tolerance

Collapsed areas can sometimes result from models with very tight tolerances:

- Global Tolerance: Increase or adjust the global tolerance settings to give the software more leeway in interpreting your model.

- Local Tolerances: Sometimes setting local tolerances for specific features can help avoid collapses without affecting the whole model.

💡 Note: Be cautious when increasing tolerances as it can affect the overall precision of your design.

3. Repairing Interferences

Interference checks are essential to identify where parts might be clashing:

- Detect Interferences: Use tools like ‘Interference Check’ to find and visualize interferences.

- Resolve: Once identified, modify parts by offsetting surfaces or modifying geometries to remove these interferences.

4. Enhancing Mesh Quality

A poor mesh can often lead to collapsed areas, especially in complex geometries:

- Mesh Refinement: Utilize meshing tools to refine areas with high curvature or complex details.

- Defeature: Sometimes, removing small features or details can improve mesh quality, thereby reducing the chances of collapses.

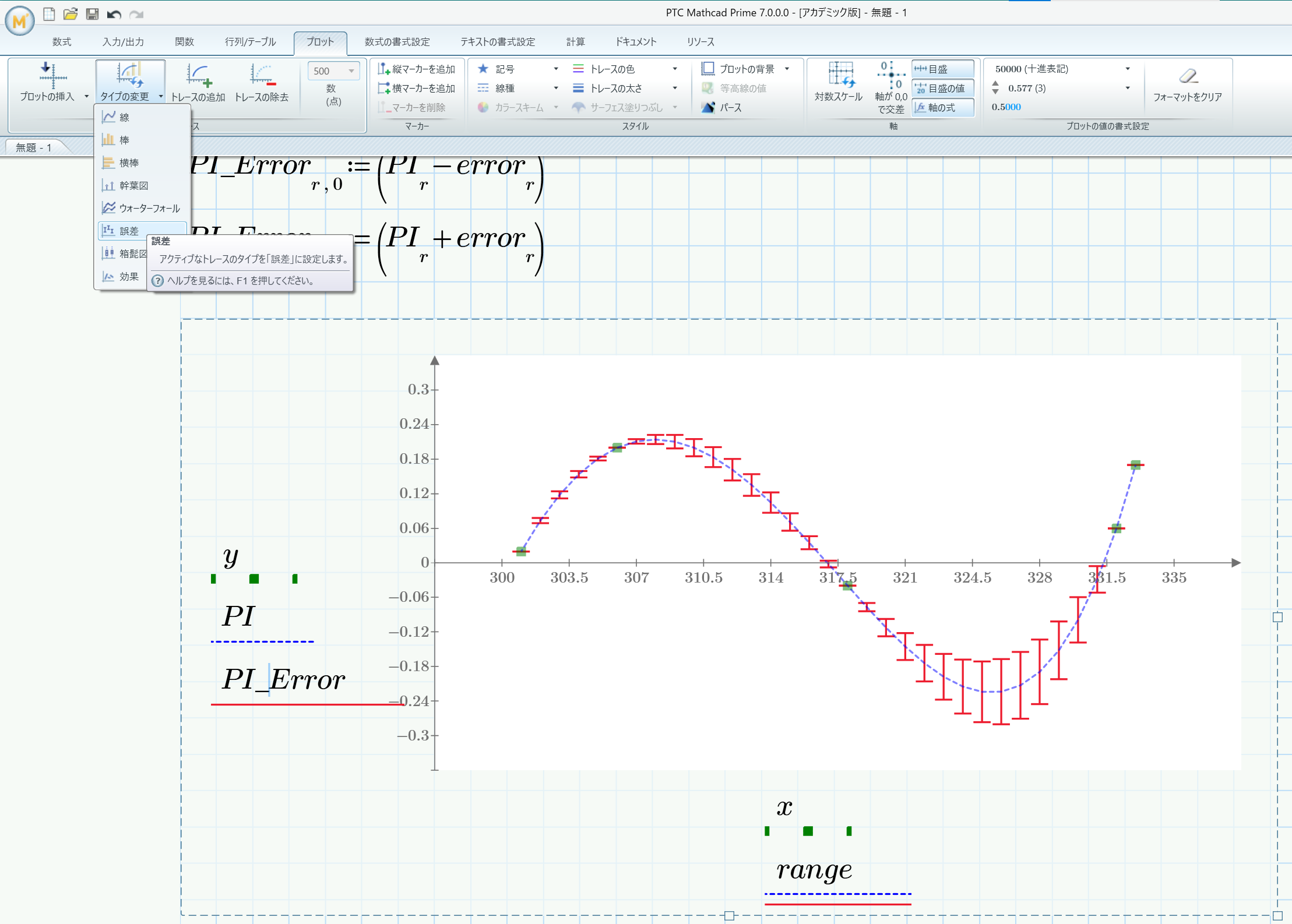

| Mesh Technique | Description |

|---|---|

| Linear | Simple, straightforward but may not capture complex geometry accurately. |

| Quadratic | Offers better representation with higher accuracy at a higher computational cost. |

5. Utilize Advanced CAD Tools

For intricate designs, employing advanced CAD tools can mitigate the risk of collapsed areas:

- Surface Heal: This tool can repair small defects in surfaces.

- Curve on Surface: It can help maintain geometric continuity and avoid collapses by ensuring accurate projection onto complex surfaces.

- Topology Optimization: This can be used to simplify models by removing unnecessary material, thus reducing complexity and potential collapse zones.

🔹 Note: Advanced tools require some learning curve but can significantly enhance your design capabilities.

By implementing these five strategies, you can address and prevent collapsed areas in your PTC MCAD work, ensuring the reliability and quality of your mechanical designs. Regular checks and adjustments are crucial to maintain high standards in your CAD work, enabling you to tackle more complex designs with confidence.

What causes areas to collapse in PTC Creo?

+

Collapsed areas can occur due to non-manifold geometry, interference between parts, very tight tolerances, or poor meshing quality.

Can increasing tolerance always prevent collapsed areas?

+

While increasing tolerance can help, it might not solve all problems and could potentially lead to reduced precision in your design.

What is topology optimization?

+

Topology optimization is a method used to optimize material distribution within a design space for a given set of loads, constraints, and goals, leading to lighter and more efficient structures.

How often should I perform interference checks?

+

It’s advisable to run interference checks after significant design changes or before proceeding to the next stage of design development.