Supply Shift Worksheet: Boost Your Inventory Planning Skills

Effective inventory planning is crucial for any business that deals with physical stock, be they in retail, manufacturing, or distribution. Inventory planning helps businesses maintain the delicate balance between overstocking and understocking, optimizing storage costs, and ensuring product availability to meet customer demand. One of the essential tools for managing this balance is the Supply Shift Worksheet. This tool can significantly boost your inventory planning skills, providing insights into stock movement, forecasting, and supply chain efficiency.

Understanding Supply Shift

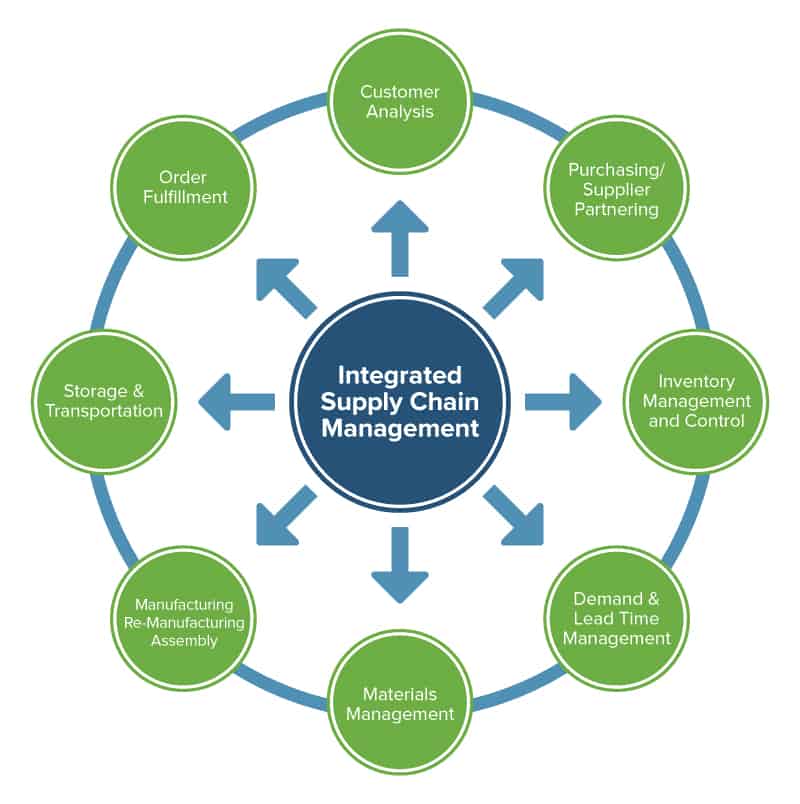

Before diving into the worksheet specifics, it’s beneficial to understand what supply shift means in the context of inventory management. A supply shift occurs when there is a change in the supply chain, which can influence inventory levels, lead times, and reorder points. Here are key elements:

- Supplier Changes: Switching suppliers can alter lead times and reliability.

- Seasonality: Demand changes due to seasonal trends affect inventory levels.

- Manufacturing Delays: Production hiccups can delay shipments.

- Product Lifecycle: The stage of a product’s lifecycle can change how inventory is managed.

Creating a Supply Shift Worksheet

To create an effective Supply Shift Worksheet, follow these steps:

- Identify Key Inventory Items: Begin with a list of products that are critical to your operations or have high turnover.

- Define Variables: Determine what variables you’ll track. These can include:

- Lead Time: Time taken from order placement to delivery.

- Order Quantity: The amount of inventory ordered in a single purchase.

- Reorder Point: The inventory level at which a new order should be placed.

- Safety Stock: Buffer stock to prevent stockouts.

- Seasonal Index: Adjustment to sales figures based on seasonal demand.

- Set Up the Worksheet: Use a layout in your worksheet with headers for:

Item Lead Time Current Stock Level Order Quantity Reorder Point Safety Stock Seasonal Index Product A 15 days 100 units 500 units 200 units 50 units 1.2 Product B 10 days 50 units 300 units 100 units 30 units 0.8 4. Input Data: Populate the table with real-time data or historical averages, adjusting for current circumstances.

5. Analyze and Adjust: Use the worksheet to:

- Adjust reorder points based on current lead times and supplier reliability.

- Optimize order quantities considering upcoming promotions or seasonal shifts.

- Set safety stock levels to mitigate risks of delays or unexpected demand.

- Project future stock levels to preempt supply shifts.

⚠️ Note: Always ensure the data in your worksheet is up to date, especially with seasonal factors or supplier changes.

Integrating Forecasting Tools

While the Supply Shift Worksheet provides a snapshot of current inventory planning, integrating forecasting tools can enhance its predictive power. Here are some ways to do so:

- Historical Data Analysis: Use past sales data to predict future trends, adjusting for any known shifts.

- Seasonality and Trends: Incorporate seasonal trends into your forecasting models.

- External Data: Include economic indicators or industry trends that might affect demand.

- Scenario Analysis: Model different supply scenarios to understand their impact on inventory planning.

Using Technology for Efficiency

Modern inventory management systems often come with features that can automate parts of your Supply Shift Worksheet. Here’s how technology can help:

- Real-Time Data Updates: Automate data entry with software that integrates with your sales and procurement systems.

- Alerts and Notifications: Set thresholds for low stock levels or delays to act proactively.

- Data Visualization: Use dashboards to visualize trends and inventory levels.

- Machine Learning: Implement predictive models for better demand forecasting.

Benefits of Effective Inventory Planning

Mastering inventory planning through tools like the Supply Shift Worksheet offers numerous benefits:

- Reduced Stockouts and Overstocks: By predicting shifts in supply, you can prevent both stock shortages and excess inventory.

- Optimized Cash Flow: Better inventory control means less capital tied up in stock.

- Increased Efficiency: Streamlined processes reduce time spent on manual inventory checks.

- Enhanced Customer Satisfaction: Consistent product availability improves customer trust and loyalty.

- Lower Storage Costs: Efficient inventory management reduces the need for extra storage space or emergency orders.

Wrapping Up

Implementing a Supply Shift Worksheet is more than just a means to an end for inventory management; it’s a strategic approach to elevate your inventory planning skills. This worksheet, when used correctly, helps you foresee potential supply chain disruptions, adjust your stock levels accordingly, and make informed decisions that align with your business objectives. By understanding the dynamics of supply shifts, incorporating forecasting tools, and leveraging technology, you can turn inventory management from a challenge into an opportunity for growth and efficiency. Remember, the key to success in inventory planning lies in the continuous review, adjustment, and optimization of your processes, ensuring that you remain agile in the ever-changing business landscape.

What is a supply shift, and why does it matter for inventory planning?

+A supply shift refers to any change in the supply chain that impacts inventory levels, lead times, or the cost of goods. It matters for inventory planning because it allows businesses to adapt their stock levels, order quantities, and reorder points to minimize disruptions, reduce excess inventory, and prevent stockouts.

How frequently should a Supply Shift Worksheet be updated?

+It’s advisable to update your Supply Shift Worksheet at least monthly. However, weekly or even daily updates might be necessary for businesses with high variability in supply and demand or when significant changes occur in the supply chain.

Can the Supply Shift Worksheet be applied to any business model?

+Yes, any business dealing with physical inventory can benefit from using a Supply Shift Worksheet. From retail to manufacturing, understanding shifts in supply is crucial for maintaining optimal inventory levels.

What are some common pitfalls when using a Supply Shift Worksheet?

+Common pitfalls include:

- Relying on outdated data.

- Not accounting for external factors like holidays or economic changes.

- Overstocking due to aggressive reorder points without assessing actual demand.

- Neglecting to integrate real-time inventory data from various sources.

How can technology enhance the use of a Supply Shift Worksheet?

+Technology can automate data entry, provide real-time updates, set alerts for critical thresholds, and employ machine learning for better demand forecasting. This integration allows for a more dynamic and responsive inventory management system.