Stainless Steel Mig Gas

Understanding the Role of Stainless Steel MIG Gas in Welding

MIG (GMAW) welding is a popular welding process that uses a continuous wire electrode and an inert gas to shield the arc. When it comes to welding stainless steel, the choice of MIG gas is crucial to ensure high-quality welds and prevent porosity, lack of fusion, and other defects. In this article, we will delve into the world of stainless steel MIG gas and explore its characteristics, benefits, and applications.

What is Stainless Steel MIG Gas?

Stainless steel MIG gas is a shielding gas mixture specifically designed for welding stainless steel alloys. The most common gas mixture used for welding stainless steel is a combination of argon (Ar), helium (He), and carbon dioxide (CO2). The gas mixture is usually provided in cylinders or bottles, and the exact composition may vary depending on the manufacturer and the specific welding application.

Characteristics of Stainless Steel MIG Gas

Stainless steel MIG gas has several key characteristics that make it suitable for welding stainless steel:

- High arc stability: The gas mixture provides a stable arc, which is essential for welding stainless steel, as it helps to prevent porosity and lack of fusion.

- Low oxygen levels: The gas mixture has low oxygen levels, which helps to prevent oxidation and promote a clean weld.

- High weld penetration: The gas mixture provides high weld penetration, which is essential for welding thick stainless steel sections.

- Low spatter: The gas mixture produces low spatter, which makes it easier to clean up the weld area and reduces the risk of porosity.

Benefits of Stainless Steel MIG Gas

Using stainless steel MIG gas offers several benefits, including:

- Improved weld quality: The gas mixture helps to produce high-quality welds with minimal porosity and lack of fusion.

- Increased productivity: The gas mixture provides a stable arc, which allows for faster welding speeds and increased productivity.

- Reduced post-weld cleaning: The gas mixture produces low spatter, which reduces the need for post-weld cleaning and minimizes the risk of porosity.

- Cost savings: Using stainless steel MIG gas can help to reduce costs by minimizing the need for rework and reducing the amount of welding consumables required.

Applications of Stainless Steel MIG Gas

Stainless steel MIG gas is commonly used in a variety of industries, including:

- Food processing: Stainless steel MIG gas is used to weld equipment and piping in the food processing industry, where high-quality welds and low contamination risks are essential.

- Pharmaceutical: Stainless steel MIG gas is used to weld equipment and piping in the pharmaceutical industry, where high-quality welds and low contamination risks are critical.

- Chemical processing: Stainless steel MIG gas is used to weld equipment and piping in the chemical processing industry, where high-quality welds and low contamination risks are essential.

- Aerospace: Stainless steel MIG gas is used to weld aircraft and aerospace components, where high-quality welds and low contamination risks are critical.

Choosing the Right Stainless Steel MIG Gas

When choosing a stainless steel MIG gas, it’s essential to consider the following factors:

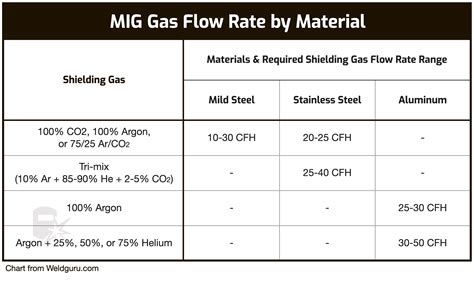

- Gas composition: The gas mixture should be specifically designed for welding stainless steel, with a high argon content and low oxygen levels.

- Flow rate: The flow rate should be adjusted according to the welding application and the thickness of the stainless steel being welded.

- Shielding: The gas mixture should provide adequate shielding to prevent porosity and lack of fusion.

Best Practices for Using Stainless Steel MIG Gas

To get the most out of stainless steel MIG gas, follow these best practices:

- Use a high-quality gas mixture: Choose a gas mixture specifically designed for welding stainless steel, with a high argon content and low oxygen levels.

- Adjust the flow rate: Adjust the flow rate according to the welding application and the thickness of the stainless steel being welded.

- Maintain a clean weld area: Keep the weld area clean and free of debris to prevent porosity and lack of fusion.

- Monitor the welding process: Monitor the welding process to ensure that the gas mixture is providing adequate shielding and that the weld quality is high.

💡 Note: Always follow the manufacturer's instructions when using stainless steel MIG gas, and consult with a welding expert if you're unsure about the best gas mixture or welding technique for your application.

In conclusion, stainless steel MIG gas is a critical component of the welding process, providing high-quality welds and preventing porosity and lack of fusion. By understanding the characteristics, benefits, and applications of stainless steel MIG gas, welders can make informed decisions about the best gas mixture and welding technique for their specific application.

What is the best gas mixture for welding stainless steel?

+

The best gas mixture for welding stainless steel is a combination of argon (Ar), helium (He), and carbon dioxide (CO2). The exact composition may vary depending on the manufacturer and the specific welding application.

How do I choose the right flow rate for stainless steel MIG gas?

+

The flow rate should be adjusted according to the welding application and the thickness of the stainless steel being welded. Consult the manufacturer’s instructions for specific guidance.

What are the benefits of using stainless steel MIG gas?

+

The benefits of using stainless steel MIG gas include improved weld quality, increased productivity, reduced post-weld cleaning, and cost savings.