5 Tips for Reading Instruments with Precision

Accurate readings from measurement tools are crucial in fields like engineering, science, and medicine. Ensuring your readings are precise can prevent costly errors, improve your results, and keep your work's credibility high. Here are five tips to help you enhance your proficiency with measuring tools.

1. Understand Your Instrument

Every measuring device has its own set of features and specifications. Whether you’re using a caliper, a thermometer, or an oscilloscope, understanding how it works is essential:

- Know the scale - Familiarize yourself with the measurement range, the smallest readable increment, and the device’s tolerance levels.

- Adjust calibration - Tools drift over time, so ensure you calibrate your instrument regularly to maintain accuracy.

- Recognize limitations - Understand the environmental conditions under which your tool performs best, as well as its limitations when faced with extreme conditions like high temperature or humidity.

2. Proper Environmental Control

The environment where measurements are taken can significantly influence the readings. Here are some considerations:

- Lighting - Proper lighting prevents parallax errors. Use a stable light source to avoid shadows or glare affecting your readings.

- Temperature and Humidity - Maintain a stable, controlled environment to avoid expansion or contraction of materials that could affect precision.

- Vibration and Movement - Minimize external vibrations that might cause the instrument to move, leading to inaccuracies.

🌡️ Note: For high-precision tasks, especially in metrology, maintaining a temperature-controlled environment can be crucial.

3. Maintain Correct Posture and Position

Your body position when reading instruments can impact precision:

- Eye Level - Keep your eyes at the same level as the scale to prevent parallax errors. Using a mirror or a stand can help.

- Angle and Orientation - Ensure the scale or digital display is perpendicular to your line of sight for the clearest reading.

- Steady Hand - Hold or stabilize the instrument to prevent shaking, which could lead to incorrect readings.

4. Use the Right Accessories

Sometimes, enhancing accuracy requires additional tools:

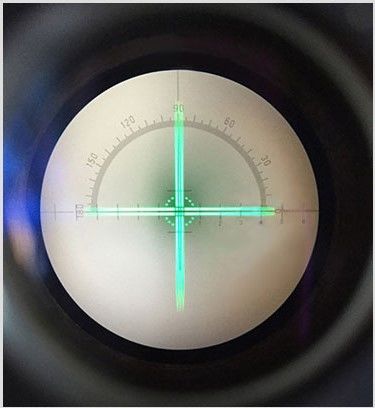

- Magnifiers - Use magnifying glasses or magnifier eyepieces to read finer scales accurately.

- Stands and Fixtures - Use instrument stands or mounting fixtures to secure the tool, keeping measurements consistent.

- Shielding - For electronic devices, shielding can help reduce electromagnetic interference affecting readings.

5. Practice Good Reading Habits

Consistent and disciplined reading techniques are key to precision:

- Read at Eye Level - Always align your eyes with the measurement to prevent parallax errors.

- Double-Check - Taking multiple readings and comparing them can highlight any inconsistencies due to human error.

- Record Immediately - Note down your readings as soon as you take them to avoid misremembered or misrecorded values.

By following these tips, you can significantly improve the precision of your instrument readings, ensuring more reliable and accurate results. Remember, mastering these skills takes time and practice, but the payoff in terms of accuracy is substantial.

Why is calibration important for precision measurements?

+

Calibration ensures that your instrument’s readings are accurate by comparing it to known standards. Over time, due to wear and environmental factors, instruments can drift from their original calibration, potentially introducing significant errors into your measurements.

Can I improve accuracy with aftermarket equipment?

+

Yes, aftermarket equipment like magnifiers or stands can help you maintain better control over the reading environment, thus enhancing accuracy. However, they are supplementary tools; the base accuracy still relies on the instrument itself.

How often should I recalibrate my instruments?

+

The frequency of recalibration depends on the instrument’s usage, the manufacturer’s recommendations, and the accuracy requirements of your work. Generally, recalibrating annually is a good rule of thumb, but some high-precision applications might require more frequent calibration.