5 Ways to Master Mechanical Advantage Answers

In an age where efficiency and optimization are paramount, mastering mechanical advantage can significantly impact various fields, from engineering to everyday problem solving. This technique allows us to perform tasks with less effort, enhance machinery performance, and manipulate heavy objects with ease. Here, we delve into 5 ways to master mechanical advantage and how to apply these principles effectively.

Understanding Mechanical Advantage

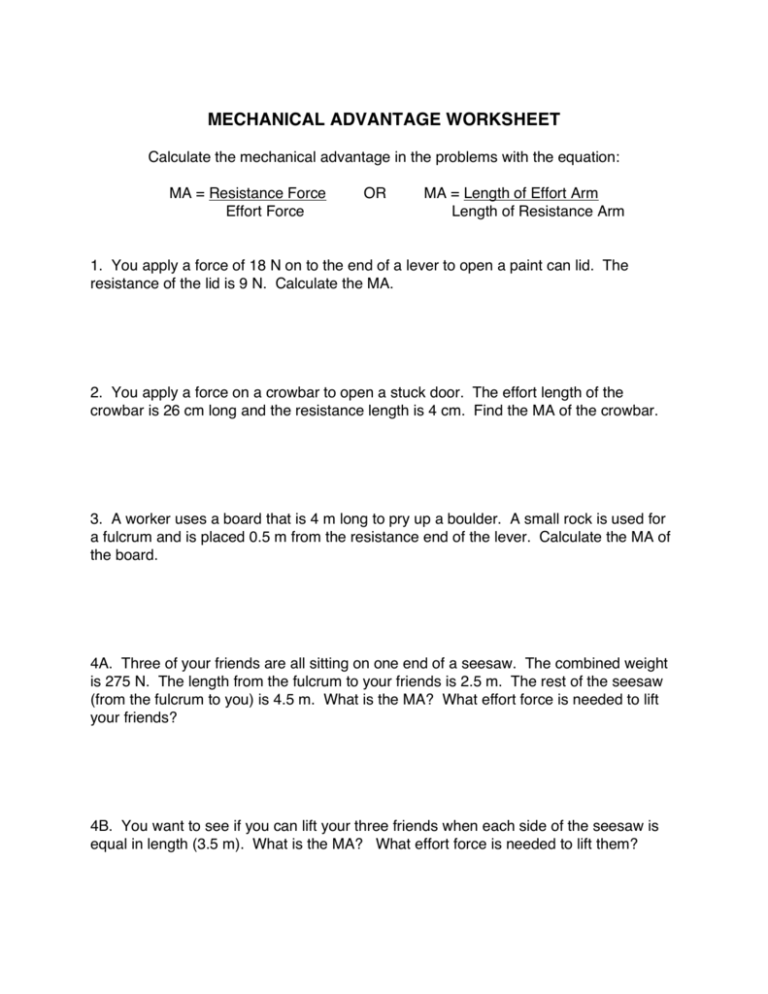

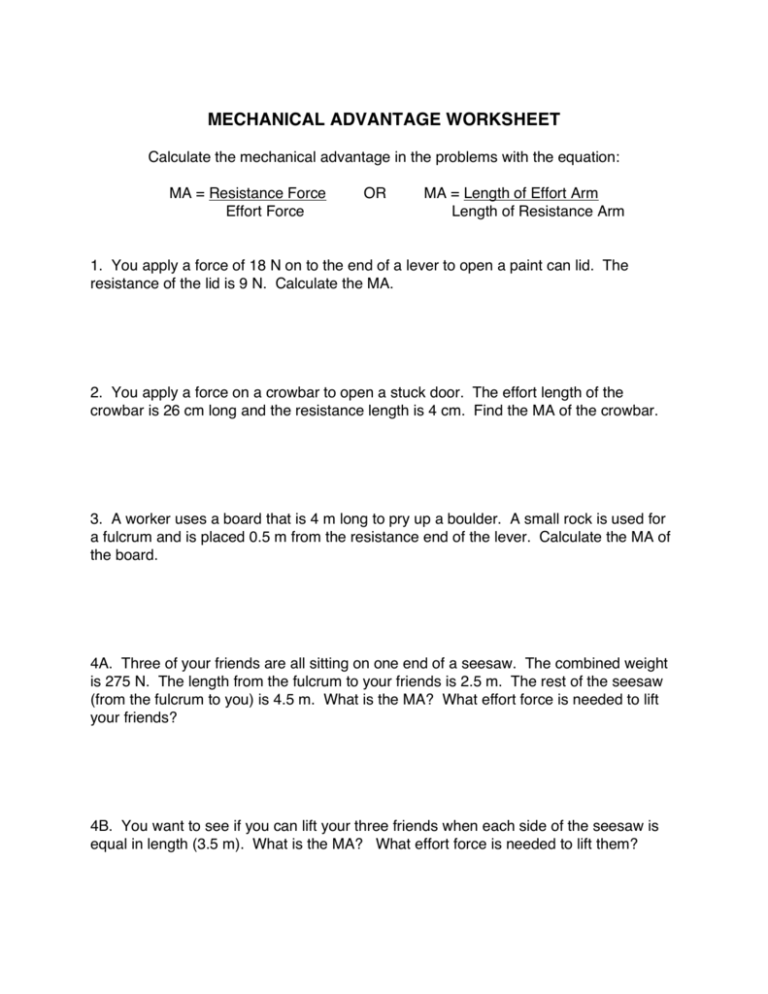

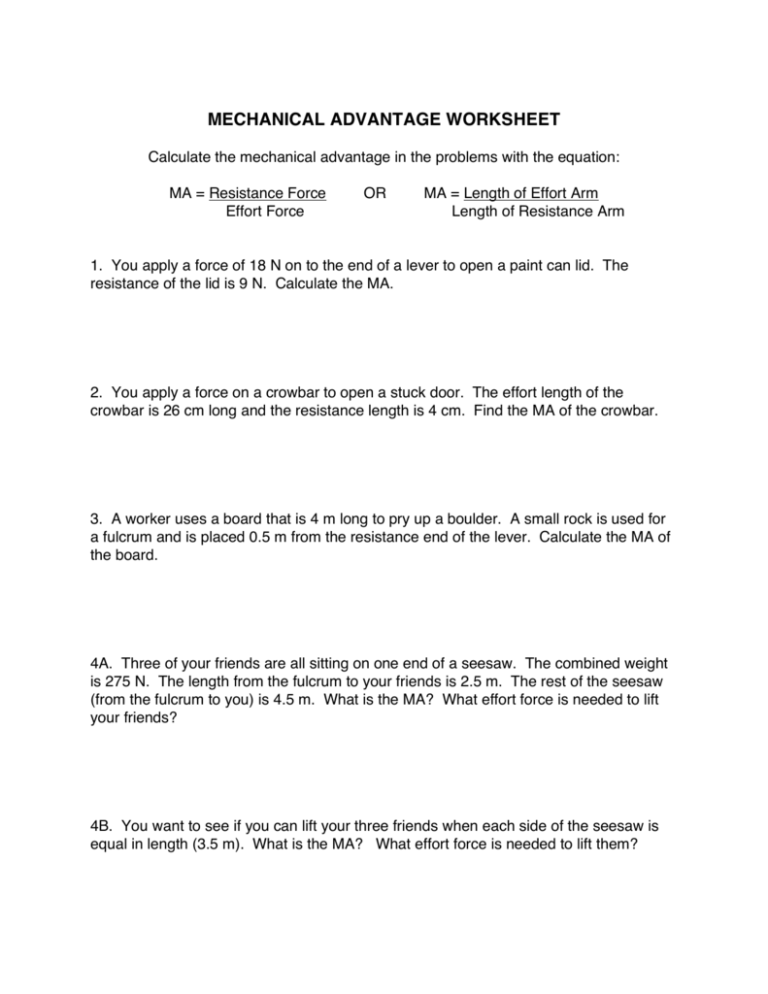

Before diving into the methods, let’s clarify what mechanical advantage means. It is the ratio of output force to the input force, which essentially allows us to amplify force to do more work with less effort. Here’s a quick glance at how different mechanical devices utilize mechanical advantage:

- Lever: Class 1, 2, and 3 levers use the distance from the fulcrum to adjust force and load.

- Pulley: Fixed, movable, and compound pulley systems redistribute load through rope.

- Wheel and Axle: A larger wheel rotating a smaller axle increases torque.

- Wedge: Splits or holds objects apart with an incline plane.

- Screw: Transforms rotary motion into linear force.

1. Leverage Through Levers

Leverage, one of the most fundamental applications of mechanical advantage, comes in various forms. Here are several ways to master lever systems:

- Class 1 Levers: Here, the fulcrum lies between the load and effort. Examples include seesaws, crowbars, and scissors. By placing the fulcrum closer to the load, you significantly reduce the effort needed to move heavy objects.

- Class 2 Levers: The load is between the fulcrum and the effort, like in wheelbarrows and nutcrackers. These levers offer a mechanical advantage greater than 1, making it easier to lift weights.

- Class 3 Levers: Unlike the others, the effort lies between the fulcrum and load in tools like tweezers or even our forearm when lifting something with our hand. While these don’t provide mechanical advantage, they offer precision and speed.

2. Maximizing Pulley Systems

Pulleys, when arranged correctly, can decrease the effort needed to lift loads significantly:

- Fixed Pulley: Changes the direction of force but does not multiply it.

- Movable Pulley: When attached to the load, it can multiply the force by the number of support ropes.

- Compound Pulley System: Combining fixed and movable pulleys can lead to substantial mechanical advantage, enabling you to lift very heavy objects with minimal effort.

⚙️ Note: Always ensure the pulley system is well-lubricated and maintains a good balance to avoid slippage or breakage.

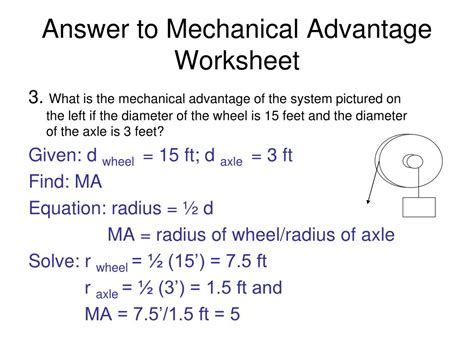

3. Wheel and Axle Mechanics

The wheel and axle system are crucial for enhancing the mechanical advantage:

- Large Diameter Wheel: A larger wheel moving a smaller axle can multiply force. Think of doorknobs, bicycle wheels, or gears.

- Gears: By using gears of different sizes, we can not only increase force but also control speed and direction.

Implementing wheel and axle systems:

- Adjust the gear ratios to match the desired force multiplication or speed adjustment.

- Use bearings to reduce friction, thereby maximizing efficiency.

4. Inclined Plane and Wedge Strategies

Inclined planes and wedges are simple yet potent tools:

- Inclined Plane: A ramp reduces the force needed to lift an object by increasing the distance over which the force is applied. For every degree less steepness, the force decreases by about 5%.

- Wedge: A wedge can split, lift, or hold things apart. The longer and thinner the wedge, the greater the mechanical advantage.

5. Screw Dynamics

Screws convert a small force into a large force along a spiral path:

- Pitch and Diameter: The ratio between the screw’s circumference and its pitch determines the mechanical advantage. A smaller pitch means higher force.

- Application: In jacks or bottle openers, screws are used to exert a large force over a small distance.

In conclusion, mastering mechanical advantage through various simple machines is not just about reducing effort but also about precision, control, and understanding how different systems can be optimized. Whether you're designing a new piece of machinery or just looking to make everyday tasks easier, these principles are invaluable. They allow us to work smarter, not harder, by utilizing the natural laws of physics to our advantage.

What is the difference between mechanical advantage and efficiency?

+

Mechanical advantage relates to the force amplification in a system, while efficiency concerns how much of the input energy is usefully transformed into output work. Efficiency considers losses due to friction and other factors, which are not directly related to mechanical advantage.

Can mechanical advantage exceed 1?

+

Yes, mechanical advantage can indeed exceed 1. For instance, a lever or pulley system can provide a mechanical advantage greater than 1 when designed correctly, allowing you to lift heavy loads with less effort.

Why do we use mechanical advantage in everyday applications?

+

Mechanical advantage reduces the physical effort required to perform tasks, making them easier and safer. This is crucial in daily life for lifting heavy items, tightening or loosening screws, or even for precise movements in surgical tools.