Master Measuring: 1/4 Inch Precision Worksheet

When it comes to projects requiring precision, such as woodworking, engineering, or model making, understanding and being able to measure and apply increments as small as 1/4 inch can make all the difference in achieving high-quality results. This blog post will guide you through the process of mastering measurements down to a quarter-inch precision, using interactive tools, practical examples, and detailed explanations.

Understanding 1⁄4 Inch Precision

A quarter inch (1⁄4 inch) is one of the most common fractions used in measurement, especially in fields where fine-tuning is crucial. Here’s what you need to know:

- Inches and Fractions: An inch is divided into several fractions, with 1/4 inch being a prominent one. If you visualize an inch as a piece of bread, a quarter of that slice would represent 1/4 inch.

- Tool Calibration: Your measurement tools must be calibrated accurately to ensure precision. Common tools include rulers, tape measures, or calipers.

📝 Note: Ensure your tools are regularly checked for accuracy, especially if they're old or frequently used.

Choosing the Right Tools

To measure with 1⁄4 inch precision, you’ll need tools that can mark or read this fraction:

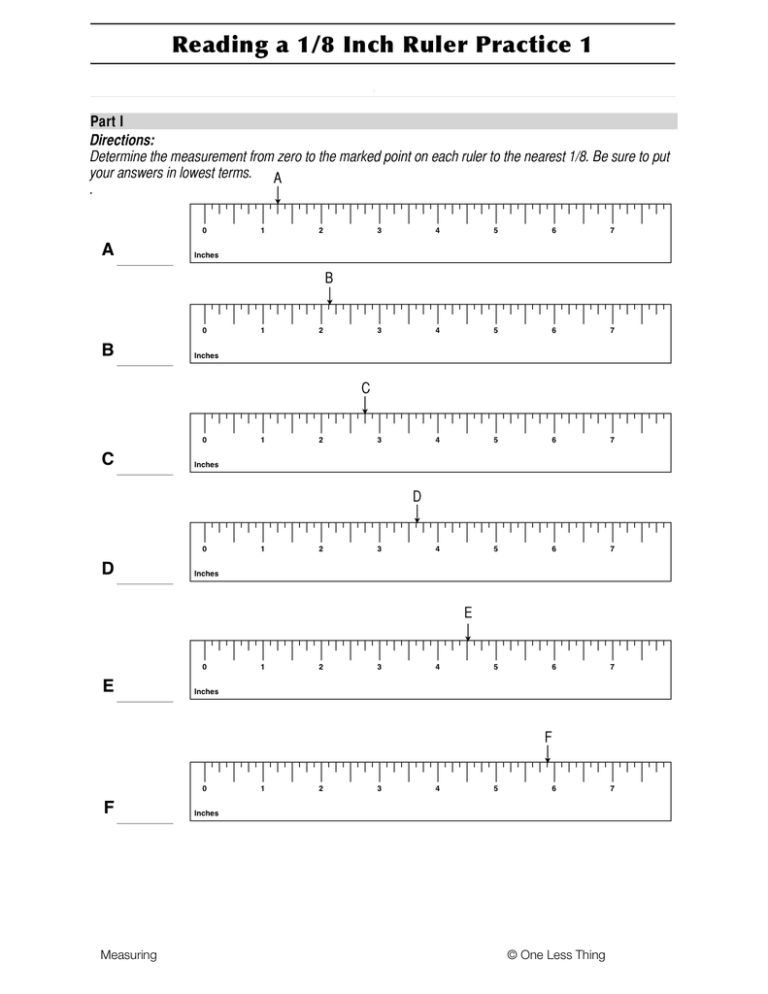

- Rulers: Look for a ruler with clear markings where each inch is divided into four equal segments.

- Tape Measures: Opt for tapes with markings that go up to at least 1/8 inch for better control over 1/4 inch measurements.

- Calipers: Digital or Vernier calipers offer the highest precision, often down to 1/64 inch or less.

| Tool | Best Used For | Considerations |

|---|---|---|

| Ruler | General measurements, marking materials | Visibility of 1/4 inch divisions |

| Tape Measure | Longer distances, flexible applications | Accuracy at small scales |

| Calipers | Precision measurements, particularly in technical projects | Cost and skill in reading measurements |

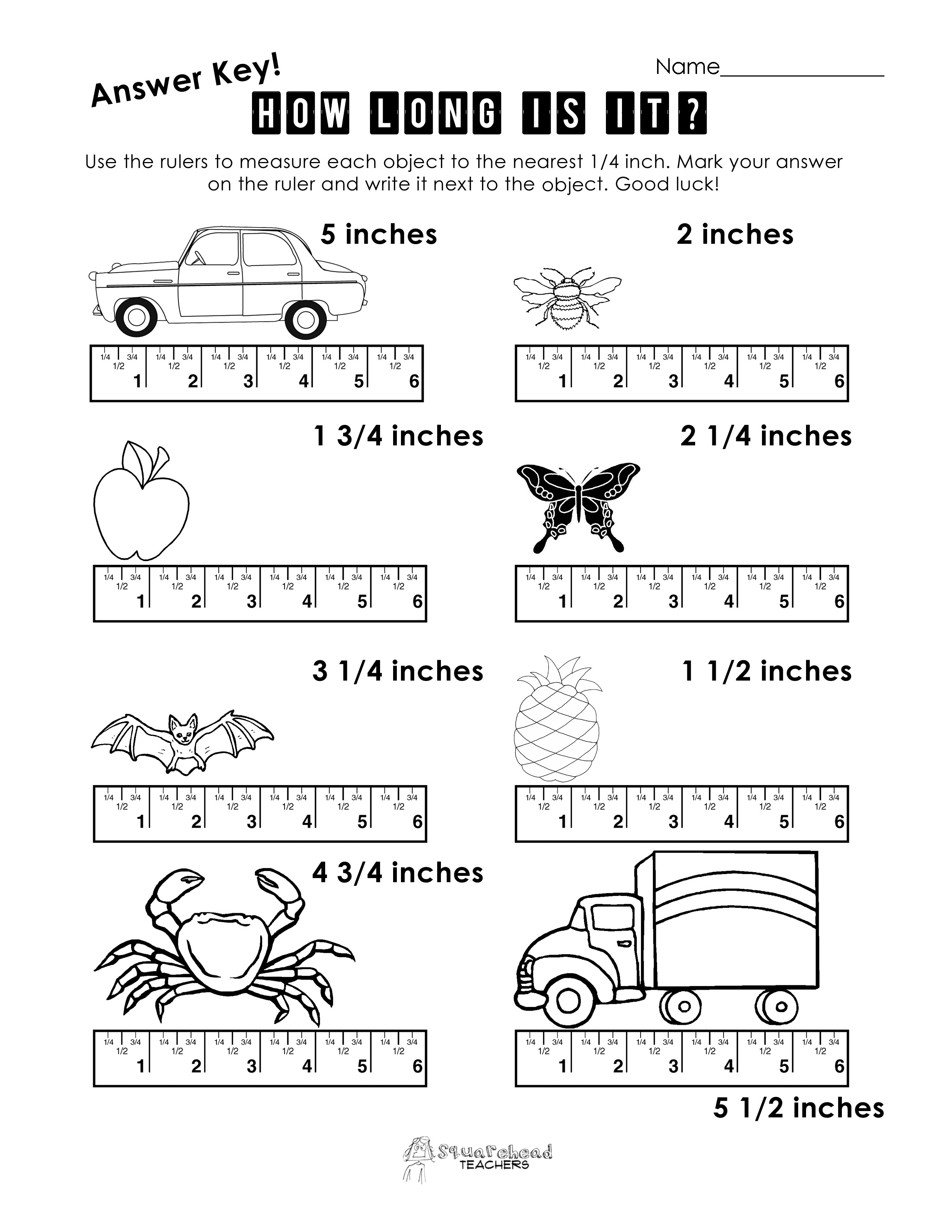

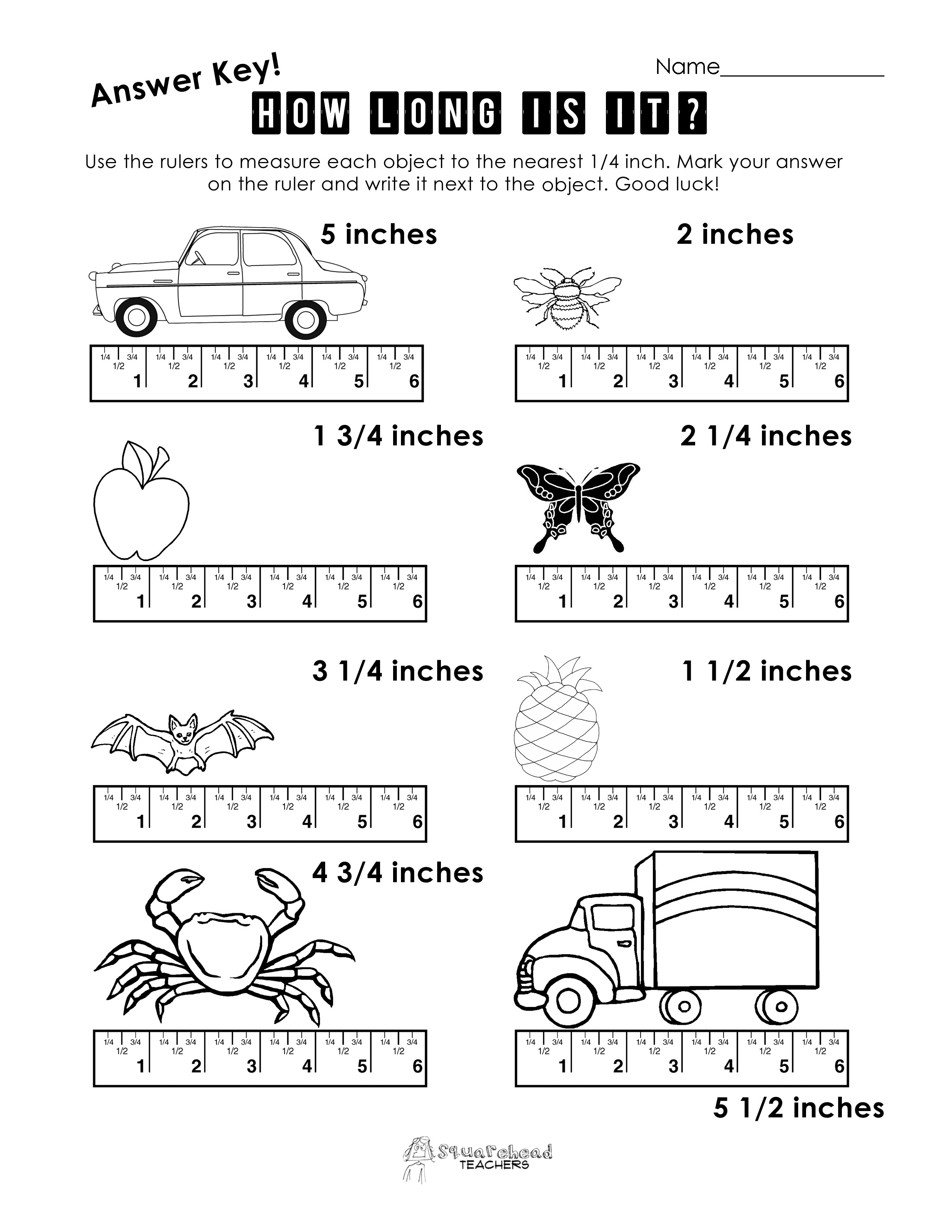

Measuring Techniques for 1⁄4 Inch

Here’s how to measure to the nearest 1⁄4 inch:

- Alignment: Ensure your measurement tool is aligned correctly with the edge of the object.

- Counting Divisions: An inch can be divided into four sections. Count these divisions:

- Zero to the first mark = 1/4 inch

- Zero to the second mark = 1/2 inch (2/4)

- Zero to the third mark = 3/4 inch

- Estimating Smaller Fractions: When you're between marks, you can estimate, but for our purposes, we'll stick to 1/4 inch accuracy.

Practical Applications

Let’s explore some scenarios where measuring to 1⁄4 inch precision is crucial:

Craft and DIY Projects

- Framing: For picture frames, 1⁄4 inch might be the margin for error in ensuring that cuts are precise.

- Model Building: Ensuring parts fit together perfectly with 1⁄4 inch gaps or seams can be essential for structural integrity.

Home Renovation

- Tile Laying: Proper spacing between tiles can often be achieved with 1⁄4 inch spacers.

- Door Trims: Trimming door frames to the right width requires precision that often goes down to 1⁄4 inch.

Technical Work

- Engineering: For machining parts, where even a 1⁄4 inch error can cause problems in assembly.

- Electronics: Space management on circuit boards often deals with 1⁄4 inch spacing between components.

Advanced Tips for Precision

- Environment Control: Temperature, humidity, and even the angle of the tool can affect your measurement accuracy.

- Checking with Multiple Tools: To avoid errors, check your measurement with more than one tool if possible.

- Practice: Like any skill, measuring accurately to 1⁄4 inch precision becomes easier with regular practice.

🎯 Note: Practice patience and take your time when measuring, especially in high-precision tasks. Small mistakes can accumulate.

In sum, mastering 1⁄4 inch precision is vital for a wide array of projects where even the smallest measurement can impact the final outcome. From selecting the right tools, understanding how to read measurements, to practical applications in crafts, renovations, and technical work, this post has provided a comprehensive guide to enhance your measuring skills. Precision not only ensures the quality of your work but also builds confidence in your craftsmanship. Keep in mind the importance of tool calibration, environmental factors, and the practice of good measurement techniques. Whether you’re a DIY enthusiast, a professional, or a hobbyist, these skills will serve you well across various projects.

What is the significance of measuring to 1⁄4 inch?

+

Measuring to 1⁄4 inch precision is significant in many fields where precision is key. It allows for better control over materials and spacing, ensuring the project’s quality and fit.

Can I use a regular ruler for 1⁄4 inch measurements?

+

Yes, if your ruler has clear 1⁄4 inch divisions. Make sure the ruler is straight, undamaged, and accurate.

How do I ensure my tools are measuring accurately?

+

Regularly check your tools against a known standard, such as a precision caliper or a calibration block. Some tools might need professional calibration.