7 Tips for Marine Diesel Engine Mechanics

Understanding the Basics of Marine Diesel Engine Mechanics

Marine diesel engines are the backbone of the maritime industry, powering everything from small fishing boats to massive cargo ships. As a marine diesel engine mechanic, it’s essential to have a deep understanding of these complex machines to keep them running efficiently and effectively. In this article, we’ll provide seven tips for marine diesel engine mechanics to help them improve their skills and stay up-to-date with the latest developments in the field.

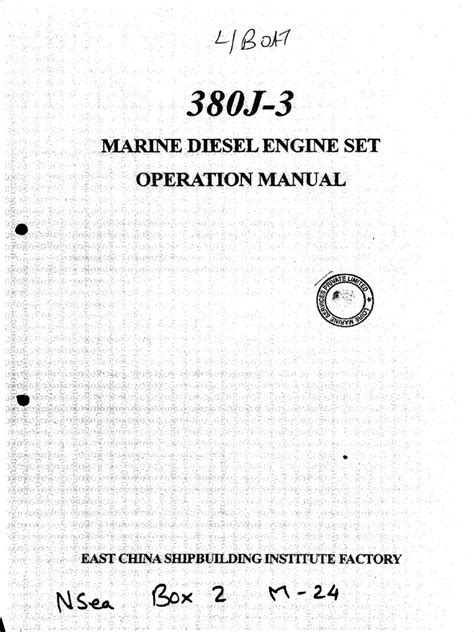

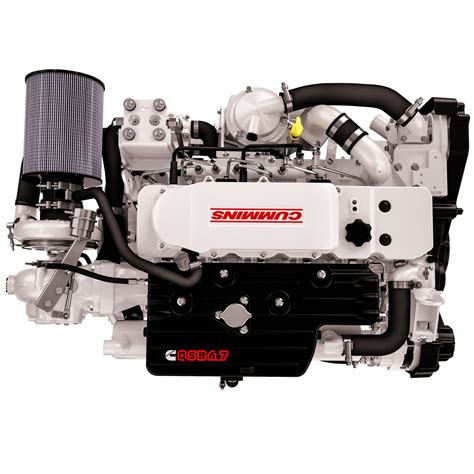

TIP 1: Familiarize Yourself with the Engine's Components

A marine diesel engine consists of several key components, including the cylinders, pistons, crankshaft, camshaft, and fuel system. Understanding how these components work together is crucial for diagnosing and repairing problems. Take the time to study the engine’s manual and familiarize yourself with each component’s function and location.

TIP 2: Use the Right Tools for the Job

Having the right tools for the job is essential for any mechanic, and marine diesel engine mechanics are no exception. Make sure you have a well-stocked toolbox with a variety of wrenches, sockets, and other specialized tools. Some essential tools for marine diesel engine mechanics include:

- A set of metric and SAE wrenches and sockets

- A torque wrench for tightening and loosening bolts

- A compression gauge for testing engine compression

- A fuel pressure test kit for diagnosing fuel system problems

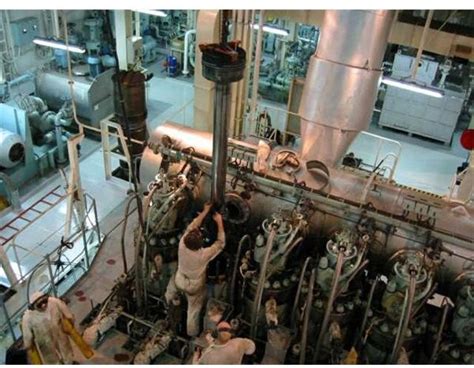

TIP 3: Keep a Clean and Organized Workspace

A clean and organized workspace is essential for staying focused and working efficiently. Make sure your workspace is well-lit and free from clutter, and that you have all the necessary tools and materials within easy reach. Consider investing in a toolbox or storage cabinet to keep your tools organized and within reach.

TIP 4: Develop a Pre-Season Maintenance Checklist

Before the busy season begins, take the time to develop a pre-season maintenance checklist to ensure your engines are running in top condition. This should include tasks such as:

- Changing the oil and filters

- Inspecting the fuel system and making any necessary repairs

- Checking the engine’s compression and adjusting the valves as needed

- Inspecting the cooling system and making any necessary repairs

TIP 5: Stay Up-to-Date with the Latest Developments in Marine Diesel Engine Technology

The field of marine diesel engine mechanics is constantly evolving, with new technologies and techniques being developed all the time. Stay up-to-date with the latest developments by attending conferences and workshops, reading industry publications, and participating in online forums and discussion groups.

TIP 6: Use Diagnostic Software to Troubleshoot Problems

Diagnostic software can be a powerful tool for troubleshooting problems with marine diesel engines. These programs can help you identify issues with the engine’s fuel system, ignition system, and other components, and provide recommendations for repairs.

TIP 7: Join a Professional Association or Network with Other Mechanics

Joining a professional association or networking with other marine diesel engine mechanics can be a great way to stay connected with others in the field and learn about new techniques and technologies. Consider joining a group such as the American Boat and Yacht Council (ABYC) or the Society of Naval Architects and Marine Engineers (SNAME).

🔧 Note: Always follow proper safety protocols when working with marine diesel engines, including wearing protective gear and ensuring the engine is properly shut down before starting work.

In conclusion, being a successful marine diesel engine mechanic requires a combination of technical knowledge, practical experience, and attention to detail. By following these seven tips, you can improve your skills and stay up-to-date with the latest developments in the field.

What are the most common problems with marine diesel engines?

+

Some of the most common problems with marine diesel engines include issues with the fuel system, ignition system, and cooling system. Other common problems include worn or damaged components, such as pistons and cylinder liners.

How often should I perform maintenance on my marine diesel engine?

+

The frequency of maintenance will depend on the specific engine and usage. As a general rule, you should perform maintenance on your marine diesel engine at least once a year, and more often if you use the engine frequently.

What are some common safety hazards associated with marine diesel engines?

+

Some common safety hazards associated with marine diesel engines include fire and explosion risks, electrical shock, and physical injury from moving parts. It’s essential to follow proper safety protocols when working with these engines.