5 Essential Lab Equipment Identification Tips

Introduction

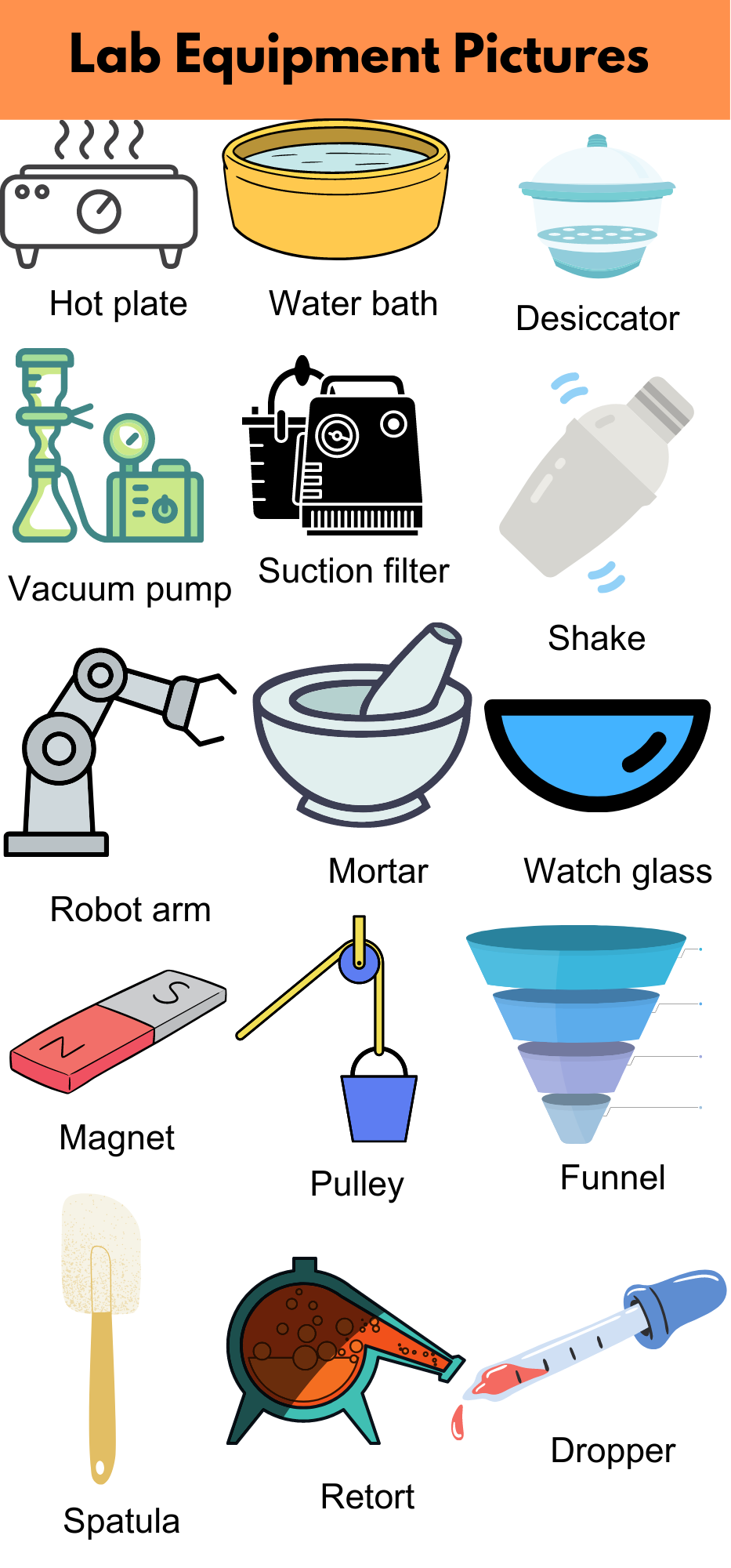

In the realm of scientific research, lab equipment plays a pivotal role in experiments, testing, and analysis. Proper lab equipment identification not only ensures safety but also improves efficiency, reliability, and accuracy of research results. This guide explores five essential tips to correctly identify and utilize various lab apparatus.

Understand the Purpose

The first step in lab equipment identification is understanding the purpose of the tool you are using:

- Measurement and Precision: Tools like pipettes, burettes, and microbalances are for precise measurements of liquids or mass.

- Observation: Microscopes for observing minute specimens at high magnifications.

- Reaction and Mixing: Beakers, flasks, and test tubes are used for mixing chemicals or observing reactions.

- Temperature Control: Bunsen burners, hot plates, or incubators for controlling environmental conditions.

Each piece of equipment serves a specific function, and knowing this function helps in:

- Choosing the right tool for the task.

- Ensuring proper use to avoid damage to equipment or samples.

- Maintaining safety standards by reducing risks associated with improper usage.

🎯 Note: Always align equipment usage with experimental design to maximize accuracy and minimize errors.

Learn the Equipment Specifications

Understanding the specifications of lab equipment is crucial:

- Capacity and Dimensions: Knowing the volume or dimensions helps in selecting the right equipment for your experiment.

<table>

<tr>

<th>Equipment</th>

<th>Typical Capacity/Size</th>

</tr>

<tr>

<td>Beaker</td>

<td>50 mL - 1 L</td>

</tr>

<tr>

<td>Pipette</td>

<td>1 mL - 10 mL</td>

</tr>

<tr>

<td>Microscope</td>

<td>40x - 1000x magnification</td>

</tr>

</table>

Tolerance: Laboratory glassware might have tolerance limits for accuracy, especially in measurement equipment.

Materials: Glassware might be made from borosilicate glass for high-temperature resistance or plastic for disposability.

Operational Range: For temperature control devices, knowing the range of temperatures they can handle is vital.

🛠️ Note: Misjudging the capacity or material type can lead to experimental inaccuracies or equipment damage.

Identify Safety Features

Safety in labs is paramount:

Protective Covers: Glove boxes or fume hoods protect against hazardous substances or fumes.

Heat Protection: Heat-resistant gloves, tongs, or holders for handling hot equipment.

Autoclavable Equipment: Ensuring that the tools can be sterilized if necessary.

Markings: Look for safety symbols, instructions, or warnings.

- Chemical Resistance: Equipment used with corrosive chemicals should have chemical-resistant coatings or materials.

- Weight Limits: Knowing the weight limits for centrifuges or balance scales to prevent overload.

⚠️ Note: Never bypass safety features or use equipment that lacks proper safety equipment for the task at hand.

Read and Understand Labels and Manuals

Labels and manuals provide critical information:

Instruction Manuals: They contain detailed operation, maintenance, and safety instructions.

Calibration and Maintenance: Periodic calibration and maintenance schedules should be noted.

Label Information: Serial numbers, model numbers, and operational instructions.

Handling and Cleaning: Specific cleaning protocols, especially for sensitive or high-precision instruments.

Utilizing Calibration Stickers

Calibration stickers might indicate:

- Date of Last Calibration: Ensuring that the equipment is current.

- Name of Calibrator: For traceability.

- Calibration Due Date: To ensure equipment remains accurate.

📚 Note: Always consult the manual before using new equipment or when in doubt about its usage.

Regular Training and Updates

Lab practices evolve, and so should your knowledge:

Lab Safety Training: Regular training sessions to update on new equipment, protocols, or safety procedures.

Equipment Familiarization: Hands-on sessions to familiarize with equipment functionalities.

Subscription to Journals and Newsletters: Keeping up with innovations and updates in lab technology.

- Refresher Courses: Periodic courses to refresh and update equipment usage skills.

- Community Engagement: Attend workshops, seminars, or conferences for deeper understanding.

💡 Note: Engaging in continuous learning ensures that lab practices remain cutting-edge and safe.

Why is it important to know the capacity of lab equipment?

+

Knowing the capacity ensures that you do not overfill or underfill, which can compromise the integrity of your experiment or damage the equipment.

What do I do if an equipment’s label is faded or missing?

+

Refer to the equipment manual or contact the manufacturer for accurate information. If unsure, consider replacing the equipment or having it serviced.

How often should lab equipment be calibrated?

+

The frequency varies by equipment type. However, annual calibration is common unless otherwise recommended by the manufacturer or lab protocols.

Can lab equipment be used for purposes other than their intended function?

+

It’s best to use lab equipment as intended to avoid safety risks and ensure experimental accuracy. Exceptions might be made with proper understanding and calibration, but caution is advised.

What are the most common safety features in lab equipment?

+

Common safety features include protective covers, heat-resistant materials, autoclavability, chemical resistance, and weight limits to ensure safe operation.