5 Essential Tools for Heavy Construction Equipment Mechanics

Introduction to Heavy Construction Equipment Mechanics

Heavy construction equipment mechanics play a vital role in ensuring that the machinery used in construction, mining, and other heavy industries operates efficiently and effectively. Their job involves diagnosing and repairing problems, performing routine maintenance, and ensuring that the equipment is in good working condition. To perform their duties, heavy construction equipment mechanics rely on a range of essential tools. In this article, we will discuss five of the most critical tools that every heavy construction equipment mechanic should have in their toolbox.

Tool 1: Multimeter

A multimeter is a versatile tool that is used to measure electrical voltage, current, and resistance. It is an essential tool for diagnosing electrical problems in heavy construction equipment. With a multimeter, mechanics can quickly identify issues such as faulty wiring, malfunctioning sensors, and faulty electrical components. When choosing a multimeter, look for one that is durable, has a high level of accuracy, and is easy to use.

🔧 Note: When using a multimeter, always follow proper safety procedures to avoid electrical shock or injury.

Tool 2: Hydraulic Pressure Test Kit

Hydraulic systems are critical components of heavy construction equipment, and a hydraulic pressure test kit is essential for diagnosing and repairing problems with these systems. The kit typically includes a pressure gauge, hoses, and adapters that allow mechanics to test hydraulic pressure, flow rate, and system performance. By using a hydraulic pressure test kit, mechanics can quickly identify issues such as leaks, blockages, and faulty pumps.

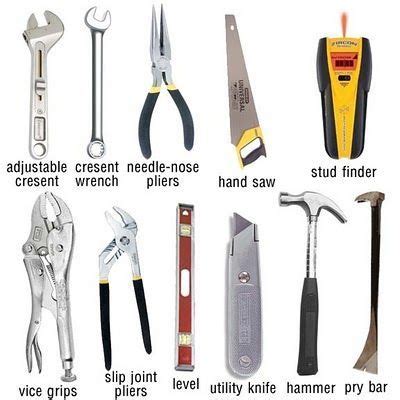

Tool 3: Impact Wrench

An impact wrench is a powerful tool that is used to loosen stubborn bolts and nuts. It is an essential tool for heavy construction equipment mechanics, as it saves time and effort when working with large, rusted, or over-torqued fasteners. When choosing an impact wrench, look for one that has a high torque rating, is durable, and has a comfortable grip.

Tool 4: Thermal Imaging Camera

A thermal imaging camera is a non-invasive tool that is used to detect temperature anomalies in heavy construction equipment. It is an essential tool for diagnosing problems with engines, transmissions, and hydraulic systems. By using a thermal imaging camera, mechanics can quickly identify issues such as overheating, cooling system leaks, and electrical problems.

Tool 5: OBD-II Scanner

An OBD-II (On-Board Diagnostics II) scanner is a tool that is used to communicate with the onboard computer system of heavy construction equipment. It is an essential tool for diagnosing problems with engines, transmissions, and other systems. By using an OBD-II scanner, mechanics can quickly identify issues such as faulty sensors, malfunctioning actuators, and software problems.

| Tool | Description | Benefits |

|---|---|---|

| Multimeter | Measures electrical voltage, current, and resistance | Quickly identifies electrical problems, reduces downtime |

| Hydraulic Pressure Test Kit | Tests hydraulic pressure, flow rate, and system performance | Quickly identifies hydraulic system problems, reduces downtime |

| Impact Wrench | Loosens stubborn bolts and nuts | Saves time and effort, reduces risk of injury |

| Thermal Imaging Camera | Detects temperature anomalies in equipment | Quickly identifies overheating, cooling system leaks, and electrical problems |

| OBD-II Scanner | Communicates with onboard computer system | Quickly identifies faulty sensors, malfunctioning actuators, and software problems |

In summary, these five essential tools are must-haves for every heavy construction equipment mechanic. They enable mechanics to quickly diagnose and repair problems, reducing downtime and increasing productivity.

What is the most critical tool for heavy construction equipment mechanics?

+

While all the tools mentioned are essential, a multimeter is perhaps the most critical tool for heavy construction equipment mechanics. It is used to diagnose electrical problems, which are common in heavy construction equipment.

How often should heavy construction equipment be maintained?

+

Heavy construction equipment should be maintained regularly, ideally every 500-1000 hours of operation. Regular maintenance helps prevent breakdowns, reduces downtime, and increases productivity.

What is the benefit of using a thermal imaging camera?

+

A thermal imaging camera helps mechanics quickly identify temperature anomalies in equipment, which can indicate overheating, cooling system leaks, or electrical problems. This enables mechanics to take corrective action before a problem becomes serious.