5 Hydraulic Uses

Introduction to Hydraulic Systems

Hydraulic systems are widely used in various industries due to their ability to provide significant mechanical advantage, making them ideal for applications where heavy loads need to be lifted or moved. The principle behind hydraulic systems is based on Pascal’s Law, which states that pressure applied to a fluid in a closed system is transmitted equally in all directions. This principle allows for the efficient transfer of force, enabling hydraulic systems to perform a variety of tasks with precision and power.

Principle of Hydraulic Systems

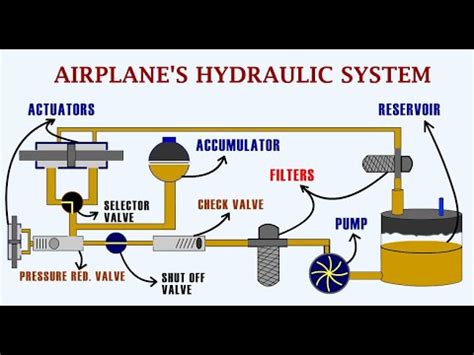

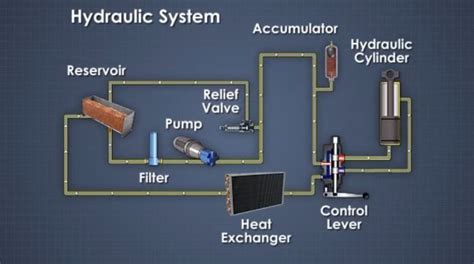

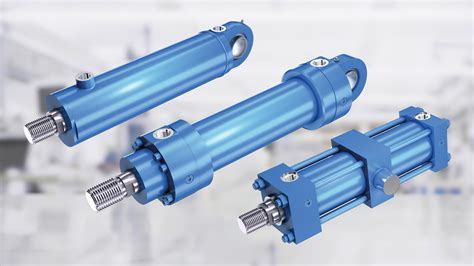

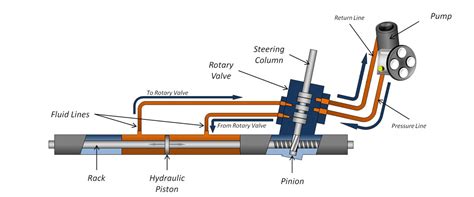

The basic components of a hydraulic system include a pump, valves, cylinders, and fluid. The pump creates the flow of fluid, which is then directed through valves to control the direction and pressure of the fluid flow. The fluid then enters a cylinder, where it applies force to a movable component, such as a piston, to achieve the desired motion or action. The fluid, typically oil, serves as the medium for transmitting the pressure. Understanding the principle of hydraulic systems is crucial for designing and operating equipment that utilizes hydraulic power.

Applications of Hydraulic Systems

Hydraulic systems have numerous applications across various industries, including construction, manufacturing, aerospace, and automotive. Here are five significant hydraulic uses: - Construction Equipment: Hydraulic systems are fundamental in operating heavy machinery such as cranes, excavators, and bulldozers. These machines rely on hydraulic power to move heavy loads, dig, and perform other construction tasks efficiently. - Manufacturing and Production: In manufacturing, hydraulic systems are used for pressing, shaping, and cutting materials. Hydraulic presses, for instance, can apply tremendous force to shape metal parts or perform other manufacturing processes. - Aerospace Industry: The aerospace industry utilizes hydraulic systems in aircraft for landing gear, flap extension, and other critical systems. The reliability and power of hydraulic systems make them indispensable in these applications. - Automotive Industry: Besides the obvious application in hydraulic brakes, the automotive industry uses hydraulic systems in power steering, suspension systems, and automatic transmissions to improve vehicle performance and comfort. - Material Handling: Hydraulic systems are also used in material handling equipment such as forklifts, where they provide the power needed to lift and move heavy loads around warehouses and distribution centers.

Benefits of Hydraulic Systems

The use of hydraulic systems offers several benefits, including: * High Power-to-Weight Ratio: Hydraulic systems can provide significant power relative to their size and weight, making them ideal for applications where space is limited. * Precise Control: Hydraulic systems allow for precise control over the motion and force applied, which is crucial in manufacturing and other precision applications. * Reliability and Durability: When properly maintained, hydraulic systems can be very reliable and durable, reducing downtime and increasing productivity. * Flexibility: Hydraulic systems can be designed to perform a wide range of tasks, from lifting heavy loads to providing precise motion control.

🔧 Note: Regular maintenance of hydraulic systems is essential to prevent fluid leaks, reduce wear on components, and ensure optimal performance.

Challenges and Future Developments

Despite the advantages of hydraulic systems, there are challenges associated with their use, such as the potential for fluid leaks and the need for regular maintenance. Future developments in hydraulic technology are focused on improving efficiency, reducing environmental impact, and integrating hydraulic systems with other technologies, such as electronics and automation systems. The development of more efficient pumps, valves, and cylinders, as well as the use of biodegradable fluids, are among the advancements aimed at enhancing the sustainability and performance of hydraulic systems.

| Component | Description |

|---|---|

| Pump | Creates the flow of fluid in the hydraulic system. |

| Valves | Control the direction and pressure of the fluid flow. |

| Cylinders | Convert the energy of the fluid into mechanical motion. |

| Fluid | The medium for transmitting pressure in the hydraulic system. |

In summary, hydraulic systems play a vital role in numerous industries due to their ability to provide significant mechanical advantage and precise control. Understanding the principle, applications, and benefits of hydraulic systems is essential for designing and operating efficient and reliable equipment. As technology continues to evolve, we can expect to see further advancements in hydraulic systems that enhance their performance, sustainability, and integration with other technologies.

What is the primary principle behind hydraulic systems?

+

The primary principle behind hydraulic systems is Pascal’s Law, which states that pressure applied to a fluid in a closed system is transmitted equally in all directions.

What are some common applications of hydraulic systems?

+

Hydraulic systems are commonly used in construction equipment, manufacturing, the aerospace industry, the automotive industry, and material handling.

What are the benefits of using hydraulic systems?

+

The benefits of using hydraulic systems include a high power-to-weight ratio, precise control, reliability, durability, and flexibility.