5 Easy Steps to Calculate Board Feet

Understanding the Basics of Board Feet

Before we jump into the steps of calculating board feet, it's essential to understand what they are. Board feet is a measurement typically used in the lumber industry to quantify wood volume. One board foot equals a piece of wood that measures:

- 1 inch thick

- 12 inches wide

- 12 inches long

This standard measure allows for easy calculation of how much lumber is needed for projects, or how much to buy when you go to a hardware store.

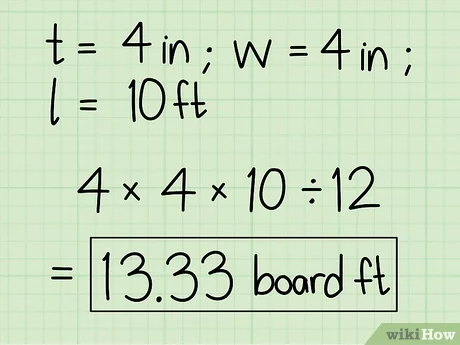

Step 1: Measure the Wood Dimensions

The first step in calculating board feet is to measure the dimensions of the wood. Here’s what you need to measure:

- Thickness - Usually measured in inches.

- Width - Also in inches.

- Length - Typically in feet.

Let's use an example. Suppose you have a piece of lumber that is 1 inch thick, 6 inches wide, and 8 feet long.

📏 Note: Make sure to measure the actual thickness rather than the nominal size, as nominal sizes refer to rough, unplaned lumber.

Step 2: Apply the Board Feet Formula

The formula to calculate board feet is:

[ \text{Board Feet (BF)} = \frac{\text{Thickness (in)} \times \text{Width (in)} \times \text{Length (ft)}}{12} ]

Using our example:

- Thickness: 1 inch

- Width: 6 inches

- Length: 8 feet

So, we have:

[ \text{Board Feet} = \frac{1 \times 6 \times 8}{12} = \frac{48}{12} = 4 \text{ BF} ]

🧮 Note: Always divide by 12 to get the board feet since this calculation converts inches to feet.

Step 3: Adjust for Fractions

If your measurements are not whole numbers, you will need to adjust for fractions. Let's say your wood is 1 inch thick, but the width is 6.5 inches, and the length is still 8 feet:

[ \text{Board Feet} = \frac{1 \times 6.5 \times 8}{12} = \frac{52}{12} \approx 4.33 \text{ BF} ]

You can either round up or down depending on your project's requirements or the purchasing policy of the lumber yard.

🔍 Note: For accurate results, use a calculator to handle complex fractions.

Step 4: Account for Waste and Defects

Real-world projects often require you to account for waste, defects in the lumber, or the need for cutting to fit. Here are some considerations:

- Waste - Typically, you might add 10% to 20% extra to your calculation to account for any potential waste.

- Defects - You may need to measure around knots or other imperfections to ensure you get usable wood.

- Cutting - If your project involves cutting several pieces from one piece of lumber, remember to account for cuts that will be made.

Using our ongoing example:

- Add 20% to our 4 board feet calculation: 4 \times 1.2 = 4.8 \text{ BF}.

🔨 Note: Including an allowance for waste can help avoid running short on materials during your project.

Step 5: Aggregate for Multiple Pieces

Often, projects require multiple boards, so you'll need to calculate the board feet for each piece and then sum them:

| Piece Number | Thickness (in) | Width (in) | Length (ft) | Board Feet |

|---|---|---|---|---|

| 1 | 1 | 6 | 8 | 4 |

| 2 | 1.5 | 8 | 6 | 6 |

| 3 | 2 | 4 | 12 | 8 |

| Total | 18 | |||

In summary:

[ \text{Total Board Feet} = 4 + 6 + 8 = 18 \text{ BF} ]

📊 Note: Always double-check your aggregation to ensure all calculations are accurate.

In conclusion, calculating board feet is a fundamental skill for any woodworker or contractor. Whether you’re estimating material for a small home project or a large construction job, understanding this basic unit of measurement ensures you have the right amount of lumber, reducing both waste and costs. By following these straightforward steps, you’ll be well-equipped to measure, adjust for factors like waste, and effectively manage your lumber needs for any project.

Why is it important to measure the actual thickness rather than the nominal size?

+

Nominal sizes are how lumber is labeled, but the actual dimensions can be less due to planing or finishing processes, which impacts the volume of usable wood.

How do I handle irregularities or non-uniform wood?

+

Use the average dimensions of the wood where irregularities exist or measure the usable part if significant defects reduce the overall size.

What if I need to adjust board feet for lumber that is not perfectly straight?

+

If the lumber is warped or bowed, measure the usable length, as you might need to trim parts of it to achieve straight cuts for your project.