Bladder for Back Panel Protection

Introduction to Bladder for Back Panel Protection

The protection of back panels in various applications, including electronics and construction, is a critical aspect of ensuring the durability and longevity of the product or structure. One innovative solution that has gained attention in recent years is the use of bladders for back panel protection. A bladder, in this context, refers to a flexible, sealed container filled with a protective material, such as air or a specialized liquid, designed to absorb shocks, distribute pressure evenly, and provide cushioning against impacts. This technology has been particularly notable in the protection of fragile components and in the construction industry for protecting walls and panels from damage.

How Bladders Work for Protection

The mechanism behind the protective functionality of bladders is based on their ability to distribute and absorb external forces. When a bladder is placed behind a panel, it acts as a buffer zone. Upon impact, the force is transferred to the bladder, which then distributes this force across its surface area. This distribution helps in reducing the pressure concentration on any single point of the panel, thereby reducing the risk of damage. Additionally, bladders can be designed to absorb shocks by allowing the protective material inside to compress and then slowly release, further mitigating the impact.

Benefits of Using Bladders for Protection

The use of bladders for back panel protection comes with several benefits, including: - Enhanced Durability: By absorbing impacts and distributing pressure, bladders significantly enhance the durability of the panels they protect. - Customizable Protection: Bladders can be tailored to meet specific protection needs by adjusting their size, material, and the type of protective fluid used. - Space Efficiency: They can be designed to fit into tight spaces, making them ideal for applications where traditional protective methods may not be feasible. - Cost-Effectiveness: In the long run, using bladders for protection can be cost-effective by reducing the need for frequent repairs or replacements.

Applications of Bladders in Protection

Bladders are used in a variety of applications for protective purposes, including: - Electronics: To protect sensitive electronic components from mechanical stress and vibration. - Construction: For protecting walls and building facades from impacts and weather conditions. - Military and Defense: In the development of protective gear and vehicles. - Aerospace: For safeguarding critical components in aircraft and spacecraft.

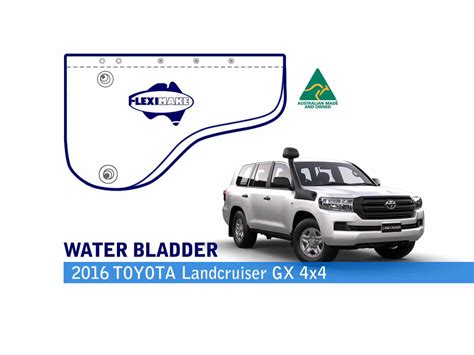

Choosing the Right Bladder for Protection

Selecting the appropriate bladder for back panel protection involves considering several factors, including: - Material: The choice between different materials (e.g., rubber, plastic, or specialized polymers) depends on the application’s requirements for flexibility, durability, and resistance to environmental factors. - Size and Shape: The bladder must fit the protected area effectively and be shaped to maximize protective coverage. - Fill Material: The type of fluid or gas used to fill the bladder can significantly affect its protective capabilities, with options ranging from air to specialized shock-absorbing liquids.

| Application | Bladder Material | Fill Material |

|---|---|---|

| Electronics | Flexible Plastic | Air or Silicone Gel |

| Construction | Rubber or PVC | Water or Polyurethane Foam |

| Military/Defense | Specialized Polymers | Shock-Absorbing Gels |

📝 Note: The selection of bladder material and fill should be based on thorough testing and consideration of the specific environmental and operational conditions of the application.

Future Developments and Innovations

The technology behind bladders for back panel protection is continually evolving, with research focusing on developing new materials and designs that offer enhanced protective capabilities. Innovations in nanotechnology and advanced polymers are expected to play a significant role in the future of bladder technology, potentially leading to the creation of lighter, stronger, and more efficient protective solutions.

In final consideration, the utilization of bladders for back panel protection represents a forward-thinking approach to safeguarding critical components and structures. By understanding the principles behind bladder technology and its applications, individuals and organizations can better navigate the complexities of protective solutions, ultimately contributing to the development of more resilient and durable products and structures. The integration of bladders into protective strategies underscores the importance of innovative thinking in addressing complex challenges, paving the way for future advancements in protection and durability.

What are bladders used for in protection?

+

Bladders are used to protect back panels and components from impacts, shocks, and pressure by absorbing and distributing external forces.

How do bladders enhance durability?

+

By acting as a buffer zone and absorbing impacts, bladders reduce the pressure concentration on any single point of the panel, thereby enhancing its durability and longevity.

What factors should be considered when choosing a bladder for protection?

+

Factors to consider include the material of the bladder, its size and shape, and the type of fill material used, all of which should be chosen based on the specific requirements of the application.