5 Tips for Armor Piercing Discarding Sabot Success

Understanding Armor Piercing Discarding Sabot (APDS) Ammunition

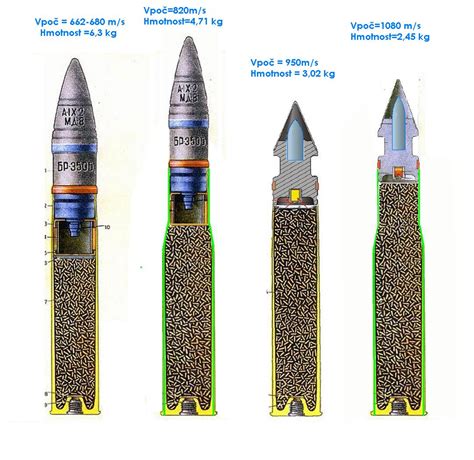

Armor Piercing Discarding Sabot (APDS) ammunition is a type of kinetic energy penetrator used in tank and anti-tank warfare. It is designed to penetrate armor by using a sub-caliber projectile with a lightweight sabot, which is discarded in flight, allowing the projectile to maintain its kinetic energy and penetrate armor more effectively. APDS rounds have been used in various forms since World War II and remain a crucial part of modern armored warfare.

Tip 1: Choosing the Right APDS Round for Your Needs

When selecting an APDS round, it’s essential to consider the type of target you’ll be engaging. Different APDS rounds are designed for specific purposes, such as:

- General-purpose APDS: Suitable for engaging a variety of targets, including armor, fortifications, and soft targets.

- Armor-piercing APDS: Optimized for penetrating thick armor, making them ideal for engaging heavily armored targets.

- High-explosive APDS: Designed to inflict maximum damage on soft targets, such as infantry and unarmored vehicles.

📝 Note: Always consult the manufacturer's guidelines and technical specifications to ensure you're using the correct APDS round for your specific needs.

Tip 2: Understanding the Importance of Muzzle Velocity

Muzzle velocity is a critical factor in determining the effectiveness of an APDS round. A higher muzzle velocity results in increased kinetic energy, allowing the projectile to penetrate armor more effectively. However, achieving high muzzle velocities can be challenging, especially in smaller caliber guns.

- Increasing muzzle velocity: Can be achieved through the use of more powerful propellants, improved barrel design, or the use of a sabot with a higher velocity.

- Optimizing muzzle velocity: Ensuring the optimal muzzle velocity for your APDS round can significantly improve its armor-piercing capabilities.

Tip 3: Sabot Design and Materials

The design and materials used in the sabot can significantly impact the performance of an APDS round.

- Sabot materials: Lightweight materials, such as plastic or aluminum, are commonly used in sabots to minimize weight and maximize velocity.

- Sabot design: A well-designed sabot should provide a stable and consistent flight path, ensuring the projectile maintains its kinetic energy and penetrates armor effectively.

Tip 4: Gun and Barrel Maintenance

Proper gun and barrel maintenance is crucial for optimal APDS performance.

- Regular cleaning: Regularly cleaning the gun and barrel ensures that the APDS round is seated correctly and that the barrel is free from debris, which can affect accuracy and muzzle velocity.

- Barrel wear: Monitoring barrel wear and replacing the barrel when necessary can help maintain optimal muzzle velocity and accuracy.

Tip 5: Training and Practice

Finally, training and practice are essential for successful APDS employment.

- Operator training: Ensuring that gunners and loaders are properly trained in the use and handling of APDS rounds is critical for effective employment.

- Practice and drills: Regular practice and drills help gunners develop the necessary skills to accurately and effectively engage targets with APDS rounds.

In summary, successful APDS employment requires careful consideration of the right round for the job, muzzle velocity, sabot design and materials, gun and barrel maintenance, and thorough training and practice.

What is the primary advantage of using APDS ammunition?

+

The primary advantage of using APDS ammunition is its ability to penetrate armor more effectively than traditional kinetic energy penetrators.

What factors affect the performance of an APDS round?

+

Factors affecting APDS performance include muzzle velocity, sabot design and materials, gun and barrel maintenance, and operator training and practice.

How often should gun and barrel maintenance be performed?

+

Regular gun and barrel maintenance should be performed according to the manufacturer’s guidelines, typically after a specified number of rounds have been fired.

Related Terms:

- APHEFSDSHEATHECBC

- First APFSDS

- Apcr

- Heatfs

- APCBC

- APFSDS shell