Airplane Mechanic Job Description and Responsibilities Revealed

What is an Airplane Mechanic?

An airplane mechanic, also known as an aircraft maintenance technician, is a skilled professional responsible for ensuring the airworthiness and safety of aircraft. They perform routine maintenance, repairs, and inspections on airplanes to guarantee they are in good working condition and comply with regulatory standards.

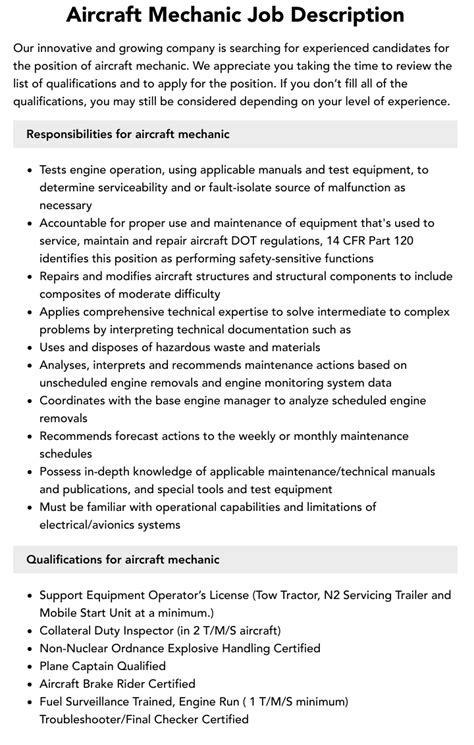

Key Responsibilities of an Airplane Mechanic

The primary duties of an airplane mechanic include:

- Pre-Flight Inspections: Conduct thorough inspections of aircraft before flight to identify and address any potential issues.

- Maintenance and Repairs: Perform routine maintenance tasks, such as oil changes, tire rotations, and brake pad replacements. They also repair or replace damaged or faulty components, including engines, landing gear, and avionics systems.

- Troubleshooting: Diagnose and troubleshoot problems with aircraft systems, including electrical, hydraulic, and pneumatic systems.

- Compliance with Regulations: Ensure all maintenance and repair work complies with Federal Aviation Administration (FAA) regulations and guidelines.

- Record Keeping: Maintain accurate and detailed records of maintenance, repairs, and inspections performed on aircraft.

- Collaboration with Pilots and Other Technicians: Work closely with pilots and other technicians to identify and address any issues with aircraft.

Skills and Qualifications Required

To become a successful airplane mechanic, an individual should possess the following skills and qualifications:

- Formal Education: Hold a high school diploma or equivalent, and complete a program in aircraft maintenance technology from a FAA-approved institution.

- Certification: Obtain certification from the FAA as an airframe and powerplant (A&P) mechanic.

- Technical Knowledge: Possess a strong understanding of aircraft systems, including electrical, hydraulic, and pneumatic systems.

- Mechanical Aptitude: Have a strong mechanical aptitude and be able to work with hand tools and specialized equipment.

- Attention to Detail: Be meticulous and detail-oriented, with a focus on safety and quality.

- Communication Skills: Have excellent communication skills, both written and verbal, to effectively collaborate with pilots, other technicians, and management.

Types of Airplane Mechanic Specializations

There are several specializations within the field of airplane mechanics, including:

- Airframe Mechanic: Focuses on the structural components of an aircraft, such as the fuselage, wings, and landing gear.

- Powerplant Mechanic: Specializes in the engines and propulsion systems of an aircraft.

- Avionics Mechanic: Works on the electrical and electronic systems of an aircraft, including navigation, communication, and radar systems.

- Line Maintenance Mechanic: Performs routine maintenance tasks, such as pre-flight inspections and tire rotations, on aircraft.

Work Environment and Safety Considerations

Airplane mechanics typically work in hangars, repair stations, or on airfields, and may be exposed to:

- Physical Demands: Lifting, bending, and standing for long periods, as well as working in cramped or awkward positions.

- Noise and Vibrations: Exposure to loud noises and vibrations from aircraft engines and equipment.

- Chemicals and Toxins: Exposure to chemicals and toxins used in maintenance and repair processes.

- Safety Risks: Risk of injury from accidents, such as falls or being struck by moving aircraft or equipment.

To mitigate these risks, airplane mechanics must follow strict safety protocols, including wearing personal protective equipment (PPE) and adhering to established safety procedures.

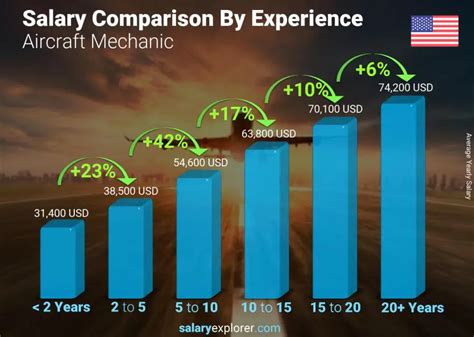

Salary and Job Outlook

The median annual salary for airplane mechanics in the United States is around $62,000, according to the Bureau of Labor Statistics (BLS). The job outlook for airplane mechanics is positive, with the BLS predicting a 5% growth in employment opportunities through 2030.

🚨 Note: The salary and job outlook figures may vary depending on factors such as location, experience, and industry.

Education and Training

To become an airplane mechanic, one must complete a program in aircraft maintenance technology from a FAA-approved institution. These programs typically take two years to complete and include both classroom and hands-on training.

📚 Note: Some colleges and universities offer bachelor's degree programs in aviation maintenance management, which can provide advanced training and qualifications.

What is the primary responsibility of an airplane mechanic?

+

The primary responsibility of an airplane mechanic is to ensure the airworthiness and safety of aircraft by performing routine maintenance, repairs, and inspections.

What skills and qualifications are required to become an airplane mechanic?

+

To become an airplane mechanic, one must possess a strong technical knowledge of aircraft systems, mechanical aptitude, attention to detail, and excellent communication skills. Additionally, formal education and certification from the FAA are required.

What is the job outlook for airplane mechanics?

+

The job outlook for airplane mechanics is positive, with the BLS predicting a 5% growth in employment opportunities through 2030.

In conclusion, airplane mechanics play a critical role in ensuring the safety and airworthiness of aircraft. By possessing the necessary skills and qualifications, and following strict safety protocols, airplane mechanics can enjoy a rewarding and challenging career in the aviation industry.

Related Terms:

- Aircraft mechanic job description resume

- Aviation mechanic salary

- Aircraft mechanic handbook

- Aircraft mechanic education requirements

- Pilot job description