5 Tips Ace Distribution Center

Introduction to Distribution Centers

A distribution center is a critical component of a company’s supply chain, serving as a central location where products are stored, sorted, and shipped to customers. The efficiency of a distribution center can significantly impact a company’s bottom line, making it essential to optimize its operations. In this article, we will discuss five tips to help you ace your distribution center operations.

Tip 1: Implement a Warehouse Management System (WMS)

A Warehouse Management System (WMS) is a software application that helps manage and control the day-to-day operations of a distribution center. A WMS can help streamline processes, improve inventory accuracy, and reduce labor costs. Some key features of a WMS include: * Inventory management: tracking inventory levels, locations, and movements * Order management: processing and fulfilling customer orders * Shipping and receiving: managing the flow of goods in and out of the distribution center * Reporting and analytics: providing insights into distribution center operations and performance

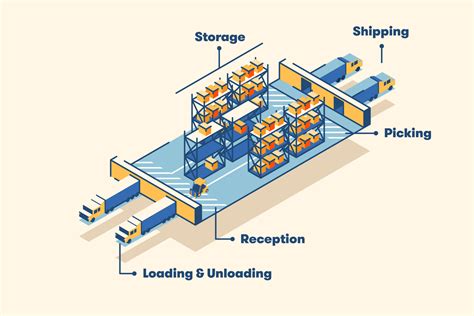

Tip 2: Optimize Your Distribution Center Layout

The layout of a distribution center can significantly impact its efficiency and productivity. A well-designed layout can help reduce travel distances, improve picking and packing operations, and increase storage capacity. Some key considerations when optimizing a distribution center layout include: * Storage capacity: maximizing the use of vertical space and minimizing wasted space * Aisle width and layout: ensuring that aisles are wide enough for easy navigation and that the layout is easy to follow * Location of receiving and shipping areas: positioning these areas to minimize travel distances and improve workflow * Location of inventory: storing fast-moving inventory in easily accessible locations and slow-moving inventory in less accessible locations

Tip 3: Implement a Pick-to-Light System

A Pick-to-Light system is a technology that uses lights to guide warehouse staff to the correct locations to pick items. This system can help improve picking accuracy, reduce picking times, and increase productivity. Some key benefits of a Pick-to-Light system include: * Improved accuracy: reducing errors and improving order fulfillment rates * Increased productivity: streamlining the picking process and reducing labor costs * Real-time tracking: providing real-time updates on picking operations and inventory levels

Tip 4: Use Data Analytics to Improve Operations

Data analytics can help distribution centers optimize their operations, improve efficiency, and reduce costs. Some key ways to use data analytics in a distribution center include: * Inventory optimization: using data to determine optimal inventory levels and reduce stockouts and overstocking * Labor optimization: using data to optimize labor schedules and reduce labor costs * Supply chain optimization: using data to optimize supply chain operations and reduce transportation costs * Performance metrics: using data to track key performance metrics, such as order fulfillment rates and shipping times

Tip 5: Invest in Employee Training and Development

Well-trained and skilled employees are essential to the success of a distribution center. Investing in employee training and development can help improve productivity, reduce errors, and increase job satisfaction. Some key areas to focus on when training distribution center employees include: * Warehouse operations: training employees on warehouse procedures, safety protocols, and equipment operation * Inventory management: training employees on inventory management procedures, including receiving, storing, and shipping * Customer service: training employees on customer service skills, including communication, problem-solving, and conflict resolution * Leadership development: training employees on leadership skills, including supervision, motivation, and team management

📝 Note: Implementing these tips can help distribution centers improve their operations, increase efficiency, and reduce costs. However, it's essential to continually monitor and evaluate operations to identify areas for improvement.

In summary, a distribution center is a critical component of a company’s supply chain, and optimizing its operations can have a significant impact on the company’s bottom line. By implementing a Warehouse Management System, optimizing the distribution center layout, implementing a Pick-to-Light system, using data analytics, and investing in employee training and development, companies can improve the efficiency and productivity of their distribution centers. These tips can help companies reduce costs, improve customer satisfaction, and increase competitiveness in the market.

What is a Warehouse Management System (WMS)?

+

A Warehouse Management System (WMS) is a software application that helps manage and control the day-to-day operations of a distribution center.

What are the benefits of a Pick-to-Light system?

+

A Pick-to-Light system can help improve picking accuracy, reduce picking times, and increase productivity.

How can data analytics be used to improve distribution center operations?

+

Data analytics can be used to optimize inventory levels, labor schedules, and supply chain operations, as well as track key performance metrics.